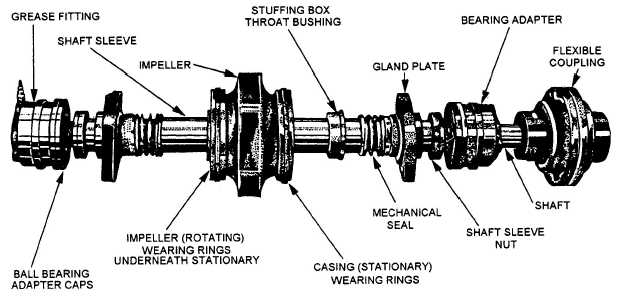

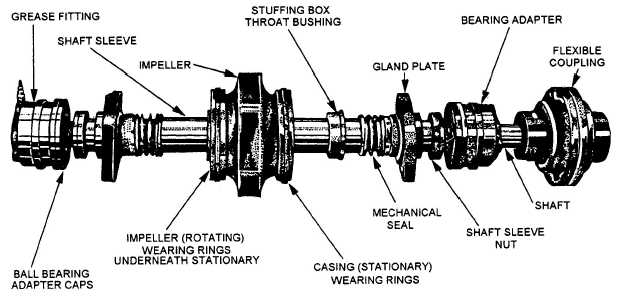

ROTATING ELEMENT. —The rotating element

(fig. 4-8) consists of an impeller and pump shaft, shaft

sleeves and nuts, ball bearings, mechanical seals, and

a flexible coupling.

Impeller and Pump Shaft. —The impeller is a

double-suction, closed impeller. It is keyed to, and

rotates with, the pump shaft. The impeller is centered

in the discharge compartment of the pump casing and

prevented from axial movement by two shaft sleeves

and two shaft nuts. The two shaft sleeves actually act

as long spacers between the impeller and shaft sleeve

nuts. The shaft sleeves are also keyed to, and rotate

with the pump shaft. Fuel enters the center part of

the impeller from both sides of the suction chamber

and is pumped into the discharge chamber. The

impeller blades are enclosed by side plates. The

blades are designed to curve backward in relation to

the rotation of the impeller to increase pump

efficiency, and impart velocity to the fuel in the

casing. Mechanical seals (fig. 4-9) fitted on the

pump shaft guard against fuel leakage from the

pump and prevent air from entering the casing

around the shaft. The seals are installed in the

stuffing boxes provided on each side of the pump

casing.

There are two types of mechanical seals, the

John Crane, and Durametalic. The principle parts of

the John Crane mechanical seal are the stationary

floating seat, low friction sealing washer, and spring.

It is a single piece unit.

The principle parts of the Durametalic

mechanical seal are the stationary insert, seal ring,

compression ring and collar assembly, and the shaft

packing. It is a three piece unit.

Figure 4-9.—John Crane mechanical seal.

NOTE

Some parts of mechanical seals are made of

carbon and break easily. Handle mechanical

seals carefully.

Bearing Cartridges. —Both ends of the pump

shaft extend outside the upper half of the casing.

Pump shaft ends are supported by ball bearings

encased in bearing cartridges and cradled in the

bearing brackets of the lower casing half. The ball

bearings absorb radial and axial thrust, and ensure

free rotation of the pump shaft. A single ball bearing

is housed in the inboard bearing cartridge, allowing

the inboard bearing some axial movement within the

cartridge. Duel ball bearings are housed in the

outboard bearing cartridge. The ball bearings are

slipped on and held firmly against a shoulder on the

pump shaft by a lock washer and locknut. The ends of

the bearing cartridges that lie closer to the center

Figure 4-8.—Assembled rotating element.

4-12