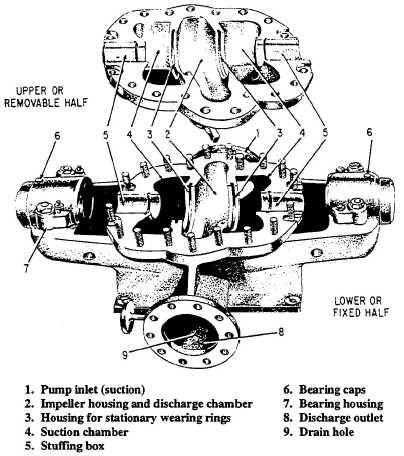

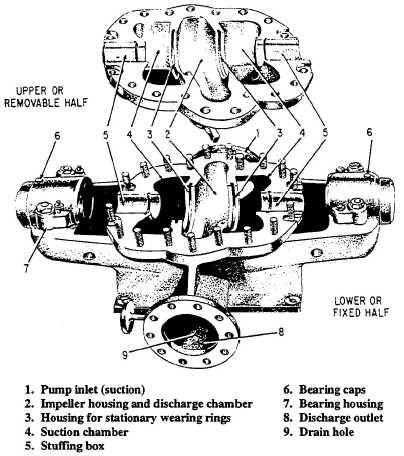

20-foot suction lift. The pump consists of a split

casing, wearing rings, and rotating element.

SPLIT CASING.— The casing (fig. 4-7). is

horizontally split at the shaft centerline. This enables

easy removal of the upper casing half for inspection

and maintenance. The casing is divided into three

chambers; two suction and one discharge. The upper

half of the casing contains a flange that may connect

the pump to an air eliminator valve. Two external

seal lines on the upper casing feed fuel from the

discharge chamber to cool the mechanical seals. The

lower half of the casing contains bearing housings, a

suction flange and a discharge flange that connect

the pump to the piping system. Drain holes and drain

plugs are provided at the bottom of both flanges for

draining the pump.

WEARING RINGS.—There are four replaceable

type wearing rings (two rotating and two stationary)

installed within the pump casing. The two rotating

are installed on the impeller. The two stationary are

installed in the pump casing between the suction and

discharge chambers. The stationary rings are held in

place and prevented from rotation by the tongue-and-

groove

construction.

When

the

pump

is

assembled, the rotating wearing rings ride inside the

stationary rings. (Check the appropriate technical

manual for the correct clearance between the

stationary and rotating rings.)

Wearing rings serve two purposes: (1) owing to

their unique construction and close tolerances, they

minimize leakage between the discharge and suction

chambers and (2) they allow for the wear created

between the impeller and pump casing.

Fuel passing through the pump has a tendency

to recirculate from the discharge chamber back to the

suction chamber. As the fuel passes through the

narrow clearance between the wearing rings, a

partial seal is made by the rapid rotation of the

impeller. This seal minimizes the leakage between

the discharge and suction chambers. After prolonged

use of the pump, the clearance between the wearing

rings gradually increases due to wear. This is caused

by the friction created by the rapid rotation of the

impeller and the fuel passing between the wearing

rings. As the clearance increases, the sealing effect

decreases resulting in the loss of the rated capacity of

the pump.

Figure 4-7.—Centrifugal pump casing.

4-11