of the pump are enclosed by bearing covers. The bearing

covers prevent bearing grease from leaking out of the

bearing cartridges. In addition, the bearing covers prevent

dirt and water, or fuel from entering the bearing cartridges.

The outside ends of the bearing cartridges are enclosed by

bearing caps. A grease cup and a grease fitting are installed

on both of the bearing caps to allow addition of grease to

the bearings. Grease reliefs are also installed to release

grease during heat expansion.

Flexible Coupling. —The flexible coupling is

designed to allow for misalignment between the motor shaft

and the pump shaft. The coupling hubs are keyed to both

the pump and motor shafts and are lubricated to reduce

wear in the coupling.

THEORY OF OPERATION. —The spinning

impeller causes fuel to leave the discharge chamber of the

pump. This creates a suction that causes a continuous flow

of fuel to the pump. Fuel from the service tank

simultaneously replenishes the fuel that leaves the suction

chamber as long as the pump has a positive suction head.

Centrifugal pumps WILL NOT draw a vacuum. Fuel in the

suction chamber enters the center part of the impeller. The

blades of the impeller propel the fuel toward the discharge

chamber walls by centrifugal force. The expanding spiral

shape of the discharge chamber slows the fuel which

increases the pressure and creates a continuous flow

through the pump. Flow is continuous as long as there is

enough fuel at the suction side, air does not enter the pump,

fuel discharge is not restricted, and the impeller rotates at

the rated speed.

MAINTENANCE. —Maintenance on the JP-5

centrifugal service pump is done in accordance with PMS

and the applicable technical manuals. Typical maintenance

is discussed in the following paragraphs.

LUBRICATION. —The importance of proper

lubrication of the ball bearings cannot be over-

emphasized. But, it is possible to over-grease the

bearings, which causes overheating and damage to the

bearings. Additionally, the wearing rings and mechanical

seals require JP-5 for lubrication. Running the pump dry

will damage these parts.

WEARING RINGS. —Wearing rings should be

inspected when the pump does not discharge at the rated

capacity. They are replaced when the radial clearance stated

in the pump’s technical manual is reached.

MECHANICAL SEALS. —Mechanical seals require

no maintenance, but should be replaced whenever leakage

occurs, or when the sealing surfaces have been disturbed.

TROUBLESHOOTING. —Table 4-2 lists typical

malfunctions, probable causes, and corrective action for the

JP-5 service pump.

Rotary Vane

Blackmer is the most commonly used rotary vane

pump in the JP-5 below decks system. These pumps come

in different sizes with different operating capacities and are

used as transfer pumps, auxiliary pumps, stripping pumps,

and on the flight deck as defuel pumps. Each pump may

vary slightly, but all are practically identical.

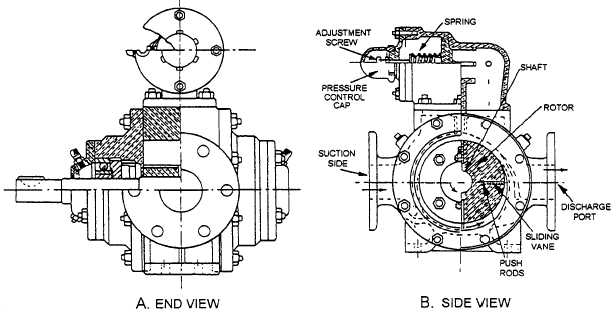

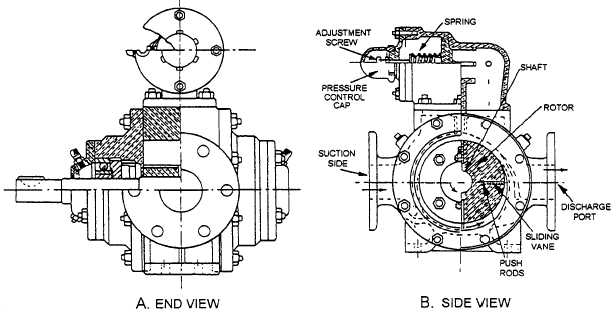

The Blackmer (fig. 4-10) is a positive displacement,

rotary vane type pump. The pumps used for stripping are

designed to pump 50 gpm at 50 psi. The pumps used

Figure 4-10.—Blackmer rotary vane pump: A. (End view); B. (Side view).

4-13