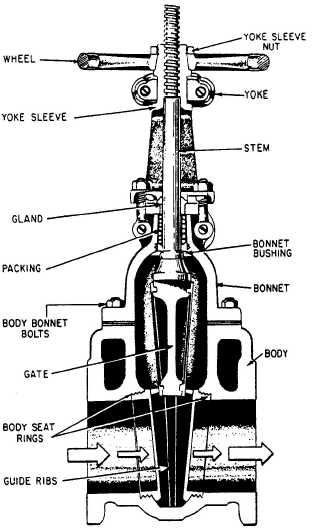

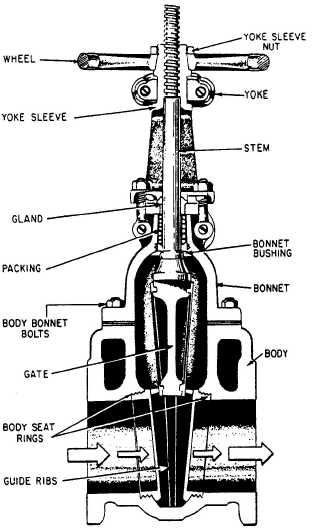

Figure 4-14.—Gate valve.

Gate valves are not designed for and cannot be used

for throttling. Most gate valves have a wedge-shaped

gate, but some have a gate of uniform thickness. The

gate is connected to the valve stem and is positioned

by rotating the handwheel. The port is the full size of

the pipe and extends through the valve.

Some types of gate valves have a rising stem,

and a glance at the valve will tell whether it is open

or closed. In the type of valve with the nonrising

stem, the stem revolves in the bonnet and the gate is

raised or lowered by the threads on the internal end

of the stem. On this type of valve, a pointer is usually

in-stalled to indicate the open or closed positions.

Gate valves operate properly with either face on

the inlet side, thus simplifying installation. Case or

forged steel valves have disks and seats made of

nickel-copper alloy, chromium steel, or a steel treated

with a hard facing material. Valve stems are made of

corrosion resistant steel. Handwheels are made of

fabricated steel, brass, or aluminum. Except for

malleable iron or aluminum handwheels, bronze gate

valves are made entirely of bronze.

NOTE

It is a good practice to put a gate valve back

together the same way it came apart. Although

the valve operates with either face on the inlet

side, after installation and use in a specific flow

pattern, one side of the valve may wear a little

differently from the other. To ensure a tight fit

and smooth operation, put it back the same

way it came out.

Globe Valves

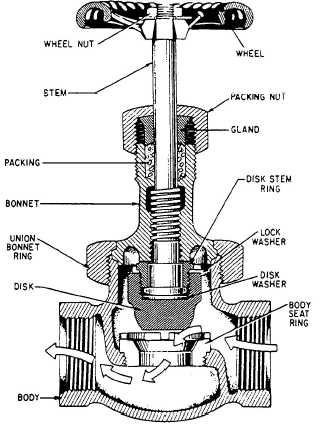

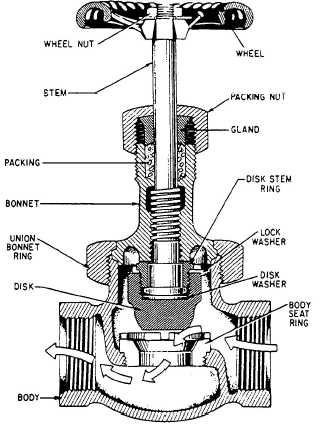

Globe valves (fig. 4-15) are so called because of

the globular shape of their bodies. It must be noted

Figure 4-15. —Globe valve.

4-19