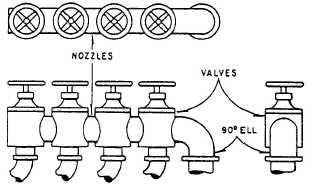

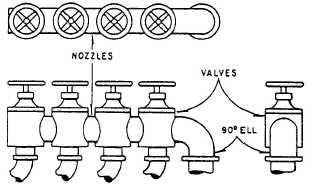

Single-Valved Manifolds

Single-valved manifolds (fig. 4-21) control flow of

JP-5 to and from storage tanks designated either JP-5

or JP-5 overflow. These ranks are not ballasted.

Single-valved manifolds are also used in the service

pump recirculating lines to recirculate fuel back to

the service tank, and as tanktop valves in the

stripping system.

The single-valved manifold is nearly identical to

the tankside half of the double-valved manifold with

one major exception. Instead of the nozzle connecting

it to a transfer mainside valve, the nozzles in a single

valve manifold connect to each other. There is NO

transfer mainside valve. A minor difference is single-

valved manifolds come in different sizes, based on

intended use. A 90-degree ell flanged on one end is

used to bolt the single-valved manifold to its

respective branch header.

Figure 4-21.—Single-valved manifold.

Flood and Drain Manifolds

Flood and drain manifolds are located in the

strip-ping system between the single-valved stripping

manifolds and the stripping pumps FOR TANKS

DESIGNATED AS JP-5 OR BALLAST only. They are

designed to direct the flow of liquids to and from the

JP-5 storage tanks during the following operations

from one central location:

When designated tanks are ballasted, they direct the

flow of sea water from the sea chest supply riser to

the single-valves stripping manifold.

When designated tanks are deballasted, they direct

the flow of ballast water from the single-valved

stripping manifold to the main drainage eductor.

When the designated tanks are stripped, they direct

the stripped liquids from the single-valved strip-ping

manifold to the suction side of the stripping pumps.

A flood and drain manifold (fig. 4-22) consists of

a manifold header and three globe type shutoff

valves.

The manifold header is a common valve body for all

three valves. It contains three valve seats and forms

an unrestricted passage between the three valves

above the valve seats. One end of the header is bolted

to the single-valved stripping manifold. The other end

is sealed. The upper part of the header houses the

valve bonnet, which provides a working area for the

valve stem. A gasket is installed between the bonnet

and the header. A packing gland in the valve bonnet

prevents liquids from leaking around the stem. The

lower part of the header, below the valve seats, has

Figure 4-22.—Flood and drain manifold.

4-25