brush connects to a linkage within the nozzle area

thermometer. It consists of a bulb connected by

control and moves in relation to the variable

a capillary tube to a Bourdon tube and a

exhaust nozzle. Current in the resistance winding

multiplying mechanism connected to a pointer.

is picked up by the movable rush, and it varies

The pointer shows the oil temperature on a dial.

according to the location of the brush. Then, this

signal current goes to one of the indicator field

coils.

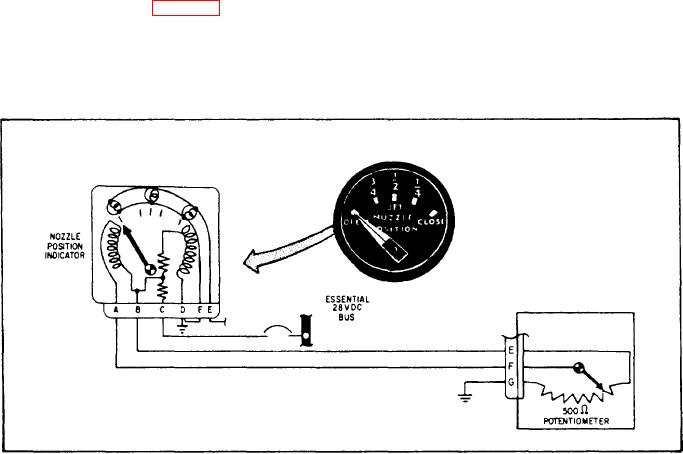

EXAUST NOZZLE INDICATING

SYSTEM

The indicator contains two field coils and

a rotor. The polarized rotor mounts on a

The exhaust nozzle position indicating system

free-moving shaft. The shaft is located in

shows the pilot engine variable exhaust nozzle

the center of the magnetic field created by the

position. This, in turn, provides a measure of

two coils. One coil connects to the transmitter

percentage of afterburning, since constant

potentiometer in the nozzle area control. The

temperatures are held throughout the afterburner

second receives a constant current to give

range.

smooth indicator operation. The rotor aligns

Each engine has a separate but identical nozzle

itself with the magnetic field. The magnetic

position indicating system. Each system consists

field varies as the signal received from the

of a transmitter potentiometer in the nozzle area

potentiometer varies. A pointer mounted on

control unit and an indicator on the main

the rotor shaft shows rotor position in relation

instrument panel. Power for the system is from

to nozzle position.

the essential 28-volt dc bus.

Each indicator is a hermetically sealed unit

TORQUEMETER SYSTEMS

containing a single receptacle for a mating plug

electrical connection. The instrument scale ranges

The electric torquemeter system in turboprop

from OPEN to CLOSE, with markings at the 1/4,

aircraft measures the torque (horsepower)

1/2, and 3/4 positions (fig. 6-61).

produced by the engine at the extension shaft.

Each system consists of a transmitter (part of the

The transmitter potentiometer consists of a

engine extension shaft), a phase detector, and an

resistance winding with a movable brush. This

Figure 6-61.-Exhaust nozzle position indicating system.