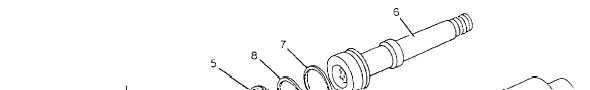

1. Cap

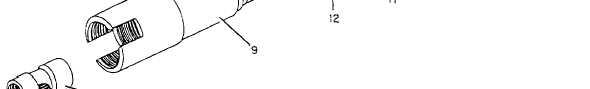

9. Piston

2. Roller boss cap

10. Seal, piston

3. Roller, the cap

11. Pin, dowel, valve

4. seal cap

12. Valve stop

5. seal cap

13. Valve slide

6. Stud

14. Seal, cylinder

7. Seal, stud and piston

15. Cylinder

8. Seal, stud

Figure 12-57.—Liquid spring shock assembly.

on the slight compressibility of liquids. Figure 12-57

illustrates the disassembled spring assembly. Most of

the internal parts are classified as nonrepairable, and

damage will require replacement of the parts at the depot

level of maintenance.

The spring assembly contains 19 cubic centimeters

of oil, MIL-S-21568. The oil is confined within the

piston cylinder assembly, and any side movement of the

arresting hook shank must be against the compressibility

of the oil. The maximum travel or compressibility of the

overall liquid spring assembly is 0.68 inch. The

operating pressure within the assembly, when bottomed

out, will be as high as 20,000 psi. In the static condition,

the oil trapped within the spring assembly is under a

return preload pressure of 350 pounds, which is created

by the reassembly of the close tolerance parts that

confine the liquid.

the

The tolerances of parts within the liquid spring and

necessity to subject certain parts to approximately

–110°F for varying lengths of time during the

disassembly and assembly process make it impractical

for it to be overhauled at the lower levels of mainte-

nance.

DAMPER CYLINDER.—The representative

arresting gear assembly employs a vertical damper

cylinder and two horizontal dampers to dampen hook

motion caused by deck impact forces. See figure 12-58.

Two centering spring assemblies maintain the hook in

the center position.

With the arresting hook lowered, the centering

springs are adjusted in the following manner:

1. Center the hook assembly.

12-66