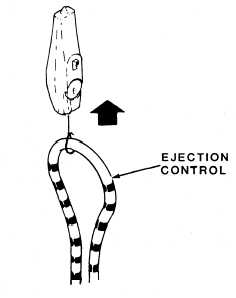

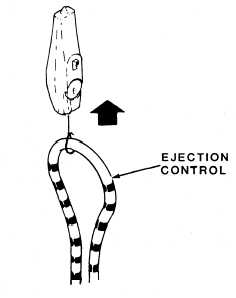

Ejection Control Assembly Check-out

Checking the ejection control assembly is a

four part procedure. The first part of the

procedures shown in figure 6-47.

1. Install the initiation pull-test tool set.

Ensure the ejection initiator pull-test tools are not

preloaded. Position the safe/arm control to the

full UP position. Attach a push-pull gauge to the

ejection control assembly. Pull upward and record

the breakout force. The breakout force should be

15 to 25 pounds.

2. Lower the safe/arm control to the full

DOWN position. Continue pulling upward on the

ejection control assembly until the pull-test tools

extend to the relaxed position. The force required

to accomplish this task should be 15 to 40 pounds.

You should ensure that the ejection control

assembly does not separate from the seat. You

should also observe the initiation rotors rotating

past the safety plunger.

3. Stow the ejection control assembly while

manually returning the initiation subsystem

rotors to the ARMED position. Then install the

initiation pull-test tool to the upper connect and

disconnect sear. At this point you can simulate

automatic seat/man separation by rotating the

emergency release handle to the full UP position.

Notice that the upper connect and disconnect sear

moves down, and the pull-test tool extends to the

relaxed position. Check to see that the T-bar is

Figure 6-47.—Ejection control assembly check-out.

in the full UP position, and that it is blocking the

initiation rotors.

4. Raise the safe/arm control to the UP and

LOCKED position. Lower the emergency release

handle to the DOWN and LOCKED position.

Remove the initiation pull-test tool set.

Inertia Reel Assembly Check-out

The inertia reel check-out may be grouped into

seven steps. The test is shown in figure 6-48.

1. Insert the bridle rod through both the

parachute riser loops. Position the inertia reel

manual control to UNLOCK. Then grasp the

center of the bridle rod and extend the risers to

mid position. Hold the risers extended and

position the inertia reel manual control lever to

LOCK. When you pull firmly on the center of the

bridle rod, the risers should not extend.

2. Slowly allow the risers to retract. The risers

retracting and ratcheting action should be audible

during retraction. The inertia reel control lever

should not snap into position, or the test results

will not be valid.

3. Slowly position the inertia reel manual

control lever to UNLOCK. Grasp the center of

the bridle rod and extend both risers to the mid

position. Exert a sharp pull on the bridle rod. The

inertia reel should lock and the risers should not

extend when a firm pull is applied. Slowly allow

the risers to fully retract, and then pull the risers

again. You should not be able to extend the risers.

4. Position the lever to LOCK, and then

UNLOCK and extend and retract the risers. The

risers should extend and retract freely.

5. Attach a push-pull gauge to the bridle rod.

Pull the gauge straight and extend the risers. You

should record the force required to extend them.

Repeat the step three to five times. The risers

should extend with a force of 5 to 15 pounds.

Allow the riser to retract slowly.

6. Position a 24-inch steel rule against the for-

ward edge of the yoke and perpendicular to the

catapult tubes. Without extending the inertia reel

straps, lift the bridle rod and measure the

normal extension of the risers. You should record

this measurement. Pull on the bridle rod and

measure the full extension of the risers. Again,

record the measurement. Allow the risers to

retract slowly. At full extension, you should

observe a minimum of 18 inches. Then, subtract

the normal measurement from the extended

measurement. The difference between the

5-66