RECEIVER.-

The receiver acts as a reservoir

for the liquid Freon 12 refrigerant. The fluid level

in the receiver varies with

system demands.

During peak cooling periods, there will be less

liquid than when the load is light. The purpose

of the receiver is to ensure that the thermostatic

expansion valve is not starved for refrigerant

under heavy cooling load conditions.

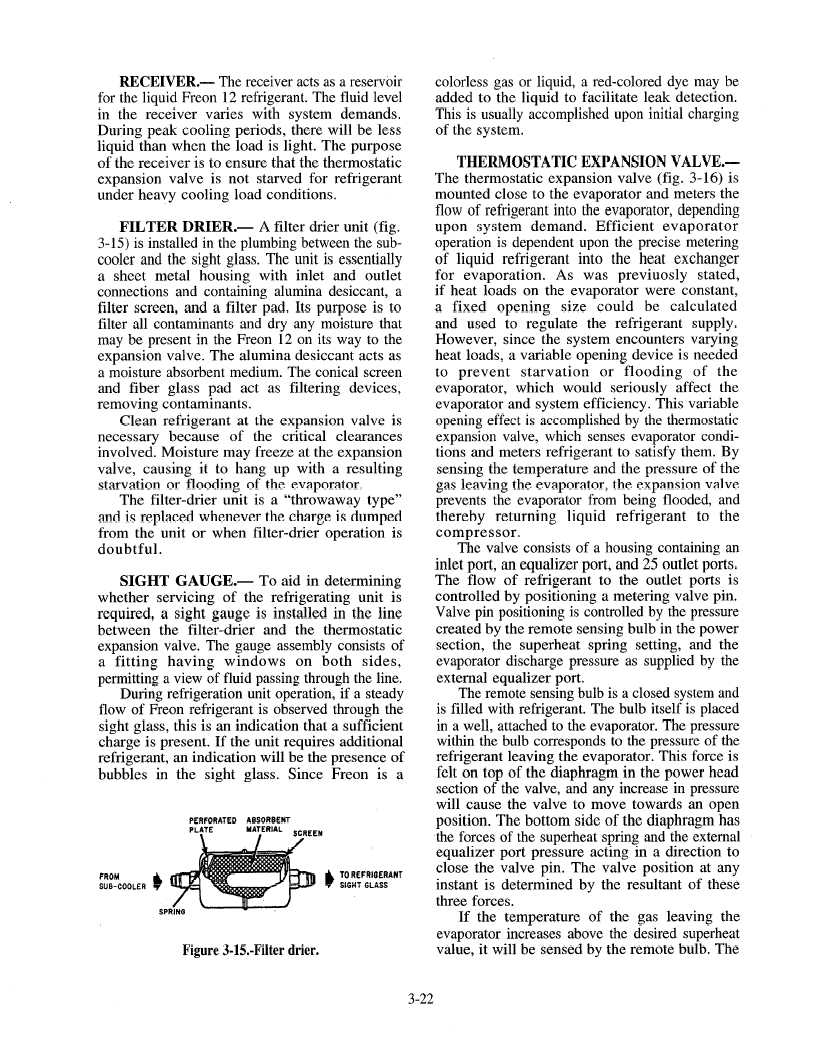

FILTER

DRIER.-

A filter drier unit (fig.

3-15) is installed in the plumbing between the sub-

cooler and the sight glass. The unit is essentially

a sheet metal housing with

inlet and outlet

connections and containing alumina desiccant, a

filter screen, and a filter pad. Its purpose is to

filter all contaminants and dry any moisture that

may be present in the Freon 12 on its way to the

expansion valve. The alumina desiccant acts as

a moisture absorbent medium. The conical screen

and fiber glass pad act as filtering

devices,

removing contaminants.

Clean refrigerant at the expansion valve is

necessary because of the critical

clearances

involved. Moisture may freeze at the expansion

valve, causing it to hang up with a resulting

starvation or flooding

of the evaporator.

The filter-drier

unit is a “throwaway

type”

and is replaced whenever the charge is dumped

from the unit or when filter-drier

operation is

doubtful.

SIGHT

GAUGE.-

To aid in determining

whether servicing of the refrigerating

unit is

required, a sight gauge is installed in the line

between the filter-drier

and the thermostatic

expansion valve. The gauge assembly consists of

a fitting

having

windows

on both

sides,

permitting a view of fluid passing through the line.

During refrigeration unit operation, if a steady

flow of Freon refrigerant is observed through the

sight glass, this is an indication that a sufficient

charge is present. If the unit requires additional

refrigerant, an indication will be the presence of

bubbles in the sight glass. Since Freon is a

PERFORATED

ABSORBENT

PLATE

.

MA:ER’AL

SCREEN

FROM

a

TO REFRIOERANT

SUB-COOLER

SiGilT

GLASS

Figure 3-E-Filter drier.

colorless gas or liquid, a red-colored dye may be

added to the liquid to facilitate leak detection.

This is usually accomplished upon initial charging

of the system.

THERMOSTATIC

EXPANSION

VALVE.-

The thermostatic expansion valve (fig. 3-16) is

mounted close to the evaporator and meters the

flow of refrigerant into the evaporator, depending

upon system demand. Efficient

evaporator

operation is dependent upon the precise metering

of liquid

refrigerant

into the heat exchanger

for evaporation.

As was previuosly

stated,

if heat loads on the evaporator were constant,

a fixed

opening

size could

be calculated

and used to regulate the refrigerant

supply.

However, since the system encounters varying

heat loads, a variable opening device is needed

to prevent

starvation

or flooding

of the

evaporator, which

would

seriously affect the

evaporator and system efficiency. This variable

opening effect is accomplished by the thermostatic

expansion valve, which senses evaporator condi-

tions and meters refrigerant to satisfy them. By

sensing the temperature and the pressure of the

gas leaving the evaporator, the expansion valve

prevents the evaporator from being flooded, and

thereby

returning

liquid

refrigerant

to the

compressor.

The valve consists of a housing containing an

inlet port, an equalizer port, and 25 outlet ports.

The flow of refrigerant

to the outlet ports is

controlled by positioning a metering valve pin.

Valve pin positioning is controlled by the pressure

created by the remote sensing bulb in the power

section, the superheat spring setting, and the

evaporator discharge pressure as supplied by the

external equalizer port.

The remote sensing bulb is a closed system and

is filled with refrigerant. The bulb itself is placed

in a well, attached to the evaporator. The pressure

within the bulb corresponds to the pressure of the

refrigerant leaving the evaporator. This force is

felt on top of the diaphragm in the power head

section of the valve, and any increase in pressure

will cause the valve to move towards an open

position. The bottom side of the diaphragm has

the forces of the superheat spring and the external

equalizer port pressure acting in a direction to

close the valve pin. The valve position at any

instant is determined by the resultant of these

three forces.

If the temperature of the gas leaving the

evaporator increases above the desired superheat

value, it will be sensed by the remote bulb. The

3-22