indication of flow and proper refrigerant charge.

The refrigerant is metered by the thermostatic

expansion valve, and then enters the evaporator

assembly. The hydraulic motor-driven evaporator

fan forces warm electronic equipment compart-

ment air through the evaporator assembly, where

it is cooled by transfer of heat to the refrigerant.

The refrigerant leaves the evaporator as a

superheated vapor.

The temperature of evaporator discharge air

to the equipment compartment is controlled by

controlling the speed of the compressor motor.

The evaporator pressure control system maintains

the refrigerant pressure within a specified range

so that the average temperature range of the

refrigerant is between 29.8° and 32.9° ± 0.6°F.

This temperature range consequently controls air

temperature to approximately 38°. The difference

between the air and refrigerant temperatures is due

to the efficiency of the heat exchanger.

If the equipment compartment temperature

increases, refrigerant pressure on the low side will

also increase. The increase in pressure is sensed

by a pressure transducer located in the compressor

inlet line, and a signal is sent to the evaporator

pressure control system amplifier. The amplifier,

in turn, sends an appropriate signal to the servo

portion of the compressor hydraulic motor calling

for a speed increase to prevent pressure increase

and thus maintain a constant refrigerant pressure.

If the temperature increase calls for a compressor

motor speed above a maximum of 12,000 rpm,

the temperature rise cannot be compensated for

and the refrigerant pressure will rise. At 250 ± 5

psi compressor discharge pressure, the high side

cutout switch will shut the vapor cycle system

down.

If the equipment compartment temperature

drops, a reverse situation exists. Compressor

motor speed will decrease to a minimum of 4,000

rpm. If the temperature at the fan inlet continues

to drop beyond the range that can be compensated

(30°F), the low-temperature cutoff switch

de-energizes the compressor power relay and shuts

down the compressor motor. The refrigerant stops

flowing while the evaporator fan motor continues

to circulate compartment air. When the fan inlet

temperature rises to 40° ± 2°F, the compressor is

cut in and refrigerant flows through the

evaporator and the subcooler and returns to the

compressor to repeat the cycle.

The purpose of each major component in the

vapor cycle system is discussed in the following

paragraphs.

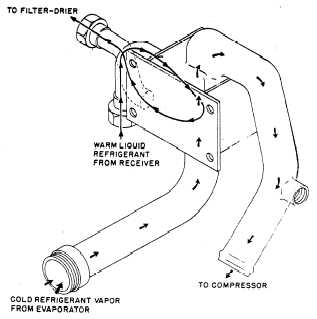

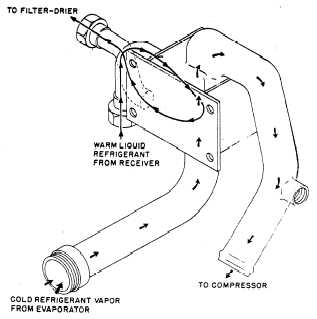

SUBCOOLER.— The subcooler (fig. 3-14) is

a heat exchanger containing passages for liquid

Freon 12 from the receiver on its way to the

evaporator and cold Freon gas leaving the

evaporator on its way to the compressor.

The purpose of the subcooler is to increase the

efficiency of the system by cooling the refrigerant

after it leaves the receiver, thereby preventing

premature vaporization or flash off after passage

through the expansion valve and before it reaches

the evaporator. As stated previously, the refrigera-

tion effect takes place when the Freon changes

state from liquid to gas. Premature flash off

would result in keeping additional refrigerant

from evaporating and would have no useful

effect on the primary cooling load required of the

package.

The liquid on the way to the thermostatic

expansion valve is relatively warm in comparison

to the cold gas leaving the evaporator. Although

the gas leaving the evaporator has absorbed heat

from the air being circulated through the

evaporator, its temperature is still in the vicinity

of 40°F. This cool gas is fed through the subcooler

where it picks up additional heat from the

relatively warm liquid Freon 12 that is flowing

from the receiver. This heat exchange causes the

liquid to be subcooled to a level that ensures

little or no flash gas on its way to the evaporator.

Figure 3-14.—Subcooler.

3-21