control receives discrepancies from sources such as

pilots, aircrews, and maintenance personnel; or

maintenance control might initiate a directed

discrepancy (such as cannibalization). After

maintenance control completes their required blocks

of the VIDS/MAF, they forward copies 1 and 5 to the

Work center for discrepancies found on the aircraft or

SE.

The work center places copies 1 and 5 on the VIDS

board under the applicable column (AWM or In

Work), as directed by maintenance control. Any time

the status of a discrepancy changes (for example, has

been In Work and goes to AWP status or back to AWM

status). maintenance control must be notified

immediately. Maintenance control must be in control

of all maintenance at all times. The VIDS/MAF should

always be kept in the appropriate column, both in the

work center and maintenance control.

Often a replacement part is required. To show

Work stoppage for parts, mark the VIDS/MAF with the

correct information in the H-Z Failed/Required

project code from maintenance control and advise

material control of the parts requirement. Finally,

move the VIDS/MAF to the AWP column of the VIDS

board. When the replacement part is received, the In

Work or AWM status is entered, as appropriate, on the

VIDS/MAF in addition to the date received in Block

B53. If maintenance control authorizes the work to be

started, the VIDS/MAF is moved to the In Work

column of the VIDS board.

NOTE: A discrepancy may go through the AWM,

In-Work, and AWP process many times before it is

corrected. If so, follow the above steps each time the

status of a discrepancy changes.

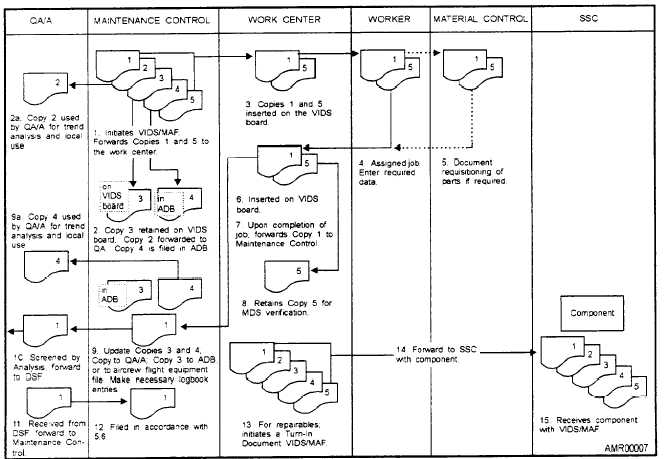

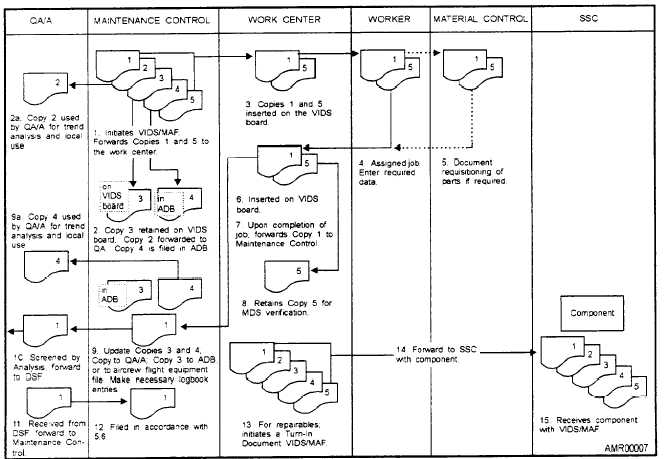

VIDS/MAF Flow

Figure 1-7 shows the VIDS/MAF flow throughout

the maintenance effort. Maintenance control is

notified when all corrective actions have been

completed. QA must be notified if any QA inspections

or check flight requirements are needed as a result of

material section. Then, obtain a supply priority and

the maintenance actions.

Figure 1-7.—Organizational maintenance (O-level) VIDS/MAF document flow chart.

1-16