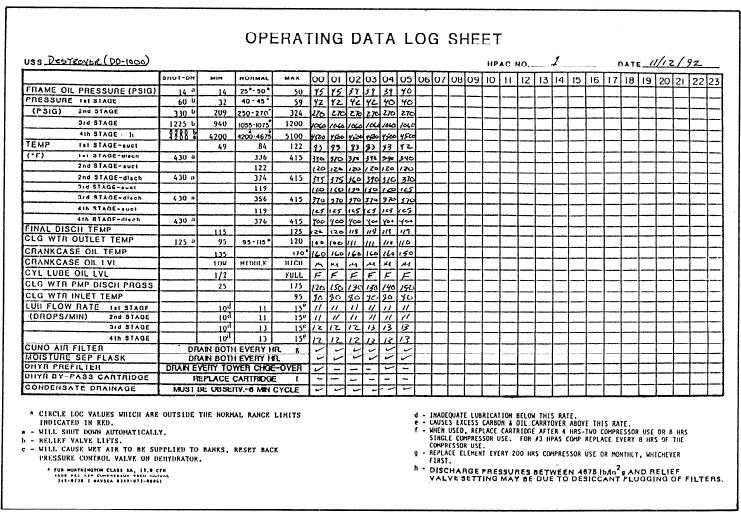

Figure 1-16.--Typical Compressor Operating Data Log.

last scaling to the day of the record and since the last

D I S T I L L I N G PLANT OPERATING REC-

scaling to the end of the day record

ORD.-- The Distilling Plant Operating Record is a daily

record of the operating ship's evaporators and their

3. Starting, stopping, and total operating time of

auxiliaries. Entries are made for each hour while the

each evaporator and various auxiliary machinery parts,

distilling plant is operating. Different gas turbine ships

such as air ejector and pumps

have many different types of distilling plants, but all

4. Remarks about the operation and maintenance

daily distilling plant operating records will require

of the distilling plant for each watch of the day

practically the same type of data entries. The following

You must make accurate entries in the Distilling

list includes the required information:

Plant Operating Record. Accurate entries will help

1. Temperature, pressure, vacuum, flow, chemical

predict trouble. If abnormal operating conditions should

analysis, and density data from various points in the

suddenly develop, the entries in the record should aid in

distilling plant

locating the sources of trouble.

2. Scaling record for each evaporator unit,

REFRIGERATION/AIR-CONDITIONING

including the date of the last scaling, the hours operated,

R E C O R D S . -- Your department will use the daily

and the quantity of distilled water produced since the

operating log for refrigeration equipment or

1-17