PACC operator to test control panel indicators.

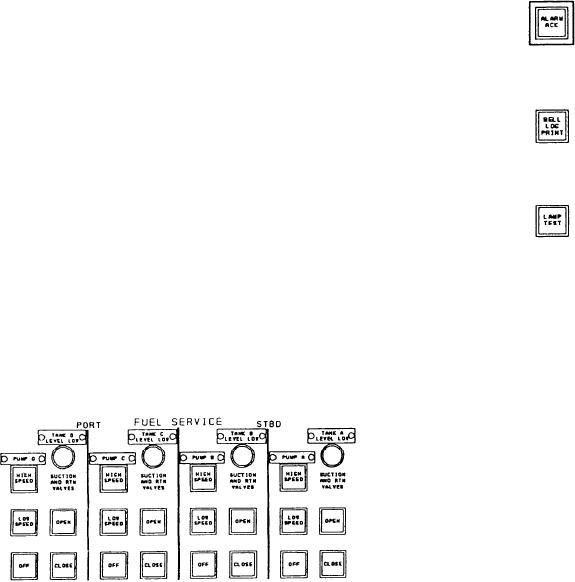

FUEL SERVICE.--Under the heading FUEL

When depressed, all indicators light, all LED

SERVICE are the controls and indicators used by

meter segments light to indicate full scale, and

the operator to monitor the port and starboard

digital displays will indicate all 8's.

fuel service system. It has an LED, three push

buttons for pump control, and two push buttons

for valve control for each of the four systems. The

systems and pumps are labeled PORT (2-B and

2-A) and STBD (1-B and 1-A). As the controls

and indicators for each system are identical, we

will describe only the port 2-B system.

The LED is located under the heading TANK

2-B LEVEL LOW. It illuminates amber when the

FO level in the service tank is below the alarm set

point. The first three push buttons are located

vertically under the heading PUMP 2-B. They are

labeled HIGH SPEED, LOW SPEED, and OFF,

respectively. Each push button illuminates green

when the pump is in the state indicated either as

a result of the automatic control feature or

operator actuation.

The last two push buttons are located under

the heading SUCTION AND RTN VALVES.

Thrust Setting Section

They are labeled OPEN and CLOSE, respectively.

These push buttons are used by the operator to

There is a thrust setting section for each shaft

open and close the FO service tank suction and

return valves. When depressed, the push buttons

(port and starboard). The sections are mirror

image so we will describe only the port thrust

illuminate green when both valves are in the

setting section. These sections are located to the

position commanded (full open or full closed).

upper left and upper right side of the programmed

control levers. Each section has an LED and

four digital displays. The LED, under the heading

EOT ALERT, illuminates amber to indicate a

difference exists between the BCU port program

control lever (order) setting and the PACC

program lever (actual) setting. Two of the digital

indicators are located under the heading SHAFT

SPEED. The first indicator is labeled ORDER

RPM. It is a three-digit display that indicates the

port shaft speed (order) as determined by the

setting of the BCU programmed control lever. The

second indicator is labeled ACK RPM. It is a

Console Section

three-digit display that indicates the port shaft

This section is located between the PROPUL-

speed (actual) demand output as determined by

the position of the PACC programmed control

SION AUX section and the port THRUST

lever.

SETTING section. It has three push buttons

mounted vertically. The first push button, labeled

The other two digital indicators are located

ALARM ACK, is used by the operator to silence

audible alarms, cause flashing alarm indicators

under the heading PROP PITCH. The first

for active alarms to go to a steady state, and

indicator is labeled ORDER PERCENT. It is a

sign plus three-digit display that indicates the

plasnia display alarm messages to change from

ordered port propeller pitch as determined by the

unacknowledged to acknowledged state. The

setting of the BCU programmed control lever. The

second push button, labeled BELL LOG PRINT

is used by the PACC operator to obtain a bell log

second indicator is labeled ACK PERCENT. It

is a sign plus three-digit display that indicates the

printout at the EOOW/LU. The last push

port propeller pitch (actual) demand output as

button, labeled LAMP TEST, is used by the

7-16