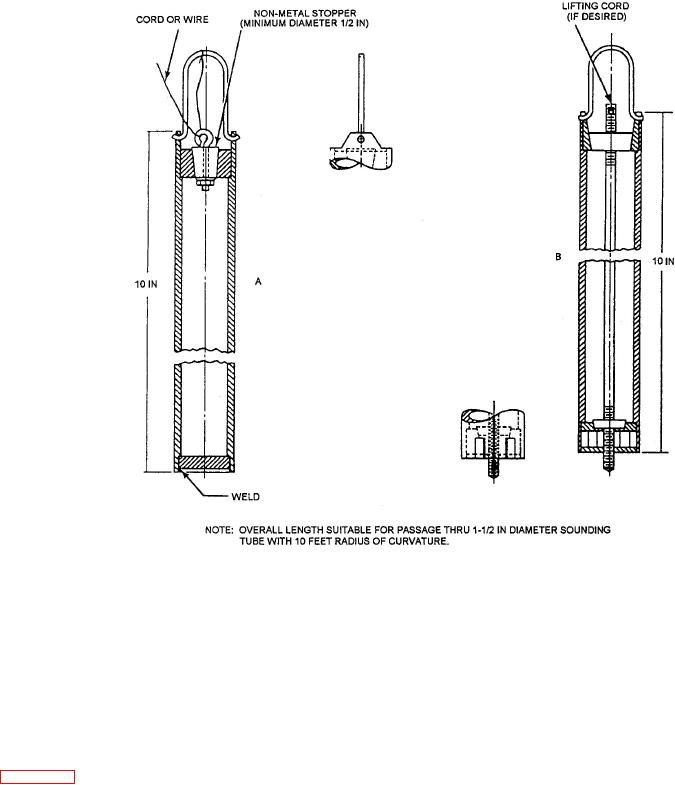

Figure 2-7.--Sounding tube oil samplers.

inspection because it is representative of the quality

Each filter/separator (coalescer) clean-fuel

and condition of the total quantity of that fuel.

discharge

METHODS AND EQUIPMENT. The methods

Each stripping pump discharge

you will use to obtain F-76 samples include tank

bottom sampling and pressurized sampling. To

All sounding tubes

perform tank bottom sampling, you will use a

common thief sampler, such as one of those shown in

For you to obtain a representative sample, the

figure 2-7. To perform pressurized sampling, you will

sounding tubes in your ship's fuel tanks must be

need standard equipment items, such as a sample

perforated along the entire length of the tube.

bottle, a bucket, rags, and the required personal

protective equipment.

Regardless of the location and method you use to

take fuel sampleswhether it is from a deck riser at a

LOCATIONS. Regardless of the type of fuel

fueling station, a thief bottom sample, or a sample

system on your ship, your ship must be equipped with

from the system pipingremember to follow the safety

valve connections at certain locations. As a minimum

precautions we have discussed and the guidelines in

requirement, your ship should at least have required

NSTM, chapter 541, "Petroleum Fuel Stowage, Use,

valve connections in the following areas:

and Testing" and chapter 542, "Gasoline and JP-5

Fuel Systems."

Each deck fill connection

STANDARDS. After you take an F-76 sample,

Each

centrifugal

purifier

clean-fuel

you must visually inspect it. In some cases, you must

discharge

determine quickly if the fuel is suitable for use or if