Outside air is drawn into the compressor

through the inlet plenum into the combustor

where it is mixed with fuel. The fuel/air

mix ture is ig nited by the ig niter plug at 10

per c ent of eng ine speed. When the unit

r eac h es 95 per c en t of eng in e speed, the

ig nition sy stem is automatically de-energ ized

bec ause at this point c ombustion is self-

sustained. The hot g ases pass from the

combustion chamber into the torus assembly .

The torus assembly directs the hot g ases onto

the thr ee tur bine wheels. By impar ting ener g y

to the tur bine wheels, the hot g ases c ause

them to rotate and prov ide shaft power for

operation

of

the

compressor,

g earbox

assembly , and dr iv en equipment. The spent

g ases are ex pelled throug h the tail pipe into

the PHM ex haust duc t.

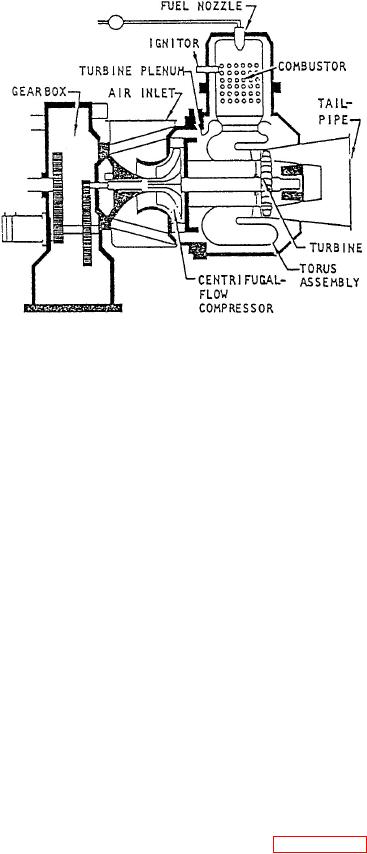

Figure 6-32.--Cutaway view showing main

components of an SSPU turbine engine.

Gearbox Assembly

The ex ternal g earbox assembly prov ides

for two of the SSPU' s mount pads and the

resilient mounts. These mounts are composed of

mou n tin g ar ea for th e SSPU' s pow er sec tion .

bonded elastomer spool pieces secured in trunnion

The internal g earbox assembly contains the

blocks.

reduction g earing that enables the power

sec tion to dr iv e the suppor ting ac c essor ies and

Normal SSPU control is maintained from the

the loading c omponents at the pr oper speed.

SSPU panel located in the EOS. The PHM electrical

When the power section is operating at 100

system allows the SSPUs to operate individually or

percent speed (41,730 rpm), the unit' s g ears

simultaneously. When both SSPUs are operating,

pr ov ide the following output speeds:

each 200-kVA, 400-Hz alternator shares the ship's

electrical load. Each SSPU is capable of supplying the

8,000 rpm

PHM's total electrical load. Reduction in electrical

load, however, is necessary for an SSPU to start the

Load compressor

8,000 rpm

LM2500 GTE.

Hydraulic pumps

3,600 rpm

Now that you have read about the general

purpose and assembly of an SSPU, let's take a closer

look at some of its main components.

Lubrication System

The

SSPU

lubrication

system

provides

SSPU Turbine Engine

lubrication for the engine and gearbox assembly, load

compressor, and generator. It is a full pressure, wet

The SSPU turbine engine is composed of four

sump system consisting of the oil pump assembly, oil

major parts: (1) a 2-stage centrifugal-flow compressor,

filter assembly, oil pressure regulator, and a check

(2) a 3-stage axial-flow turbine, (3) an inlet plenum

valve. The system is also equipped with pressure and

assembly, and (4) a combustion system. Figure 6-32 is

temperature switches and a temperature sensor for

a cutaway vie w of an SSPU turbine engine showing

readouts on the PHM indicators. The oil sump is an

the relative position of each of these components.

integral part of the SSPU assembly. The oil sump has

a capacity of 7.8 gallons and is equipped with a drain

The compressor impellers and three turbine

fitting, a dip stick, and a sight glass for monitoring

wheels are locked together by means of curvic

oil quantity. The SSPU lubrication system is

couplings. A tie bolt through the center of the wheels

serviced through a filler cap. The filler cap should

makes this assembly a single rotating unit. A floating

be removed only when the SSPU is shut down. The

ring journal bearing and seal assembly on each end of

oil

level

should

be

checked

daily.

the shaft support this rotating unit.