CAUTION

ENSURE THAT CLEANING SOLU-

TION DOES NOT ENTER THE IN-

HALATION/EXHALATION VALVE

ASSEMBLY.

Moisten a gauze pad with the cleaning solution

and wash the facepiece and housing assembly both

internally and externally.

After washing, the mask should be thoroughly

and repeatedly rinsed with warm water.

NOTE: Another alternate sanitizer,

Aerosol Antiseptic Spray SBT-12 (di-

bromosalicyl bromanicide), manufactured

by Lever Brothers, Inc., can be used.

Directions for use are indicated on the

container.

After all parts are dry, disinfect by using a

gauze pad or other lint-free wipers, with a solution

of 2 tablespoons of chlorine bleach per gallon of

water; rinse with clear water and air dry. Be

certain disinfectant reaches inner crevices of the

faceform.

To clean the delivery hose, wash it with a

cleaning solution and rinse it with clear water.

Allow all parts to air dry.

When cleaning the inhalation/exhalation valve

assembly, it will be necessary for you to obtain

a container just large enough to partially submerge

the valve. Fill the container half full of

benzalkonium chloride solution, MIL-B-37451, or

a solution of 70 percent isopropyl alcohol and 30

percent distilled water.

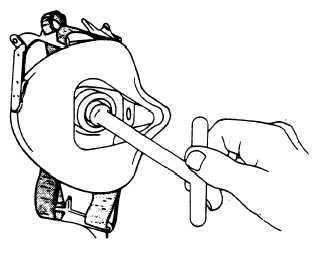

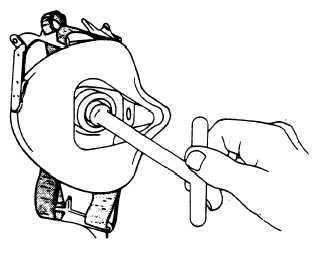

239.423

Figure 4-27.—Removing locking nut.

By using a valve wrench, as shown in figure

4-27, unscrew the valve nut and remove the

locking nut, bearing washer, and isolation washer

from the inside of the mask. This will allow the

valve, sealing washer, delivery tube, and

connector assembly to be removed as a unit from

the outside of the mask. Hold the base portion

of the valve and submerge the operating portion

of the valve into the solution. Normally, only a

few seconds are required to remove any stains and

residue. For stubborn residues, use a cotton swab

saturated with benzalkonium chloride and rub

lightly to remove. Gently shake excess solution

from oxygen valve and allow it to air dry

completely.

4-32