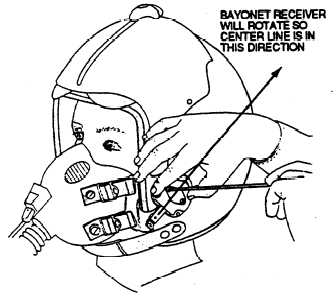

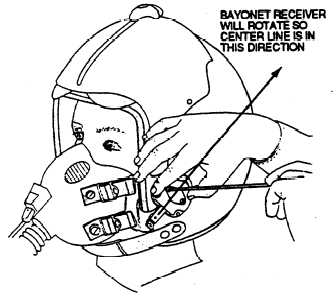

Figure 4-26.—Adjustment of bayonet receivers.

Adjustment of Bayonet Receivers

To adjust the bayonet receivers, loosen the two

adjusting screws (fig. 4-26) and rotate the receivers

until the mask fits properly. Retighten the

adjusting screws.

NOTE: Ensure that the top buckles are

tacked down prior to any adjustment.

Adjustment of the bayonet receivers is

performed with the helmet assembly and oxygen

mask assembly donned by the aircrew member.

When properly fitted, the MBU-12/P oxygen

mask can retain a pressure in excess of ambient

pressure up to the maximum pressure supplied by

the regulator.

Maintenance

Proper care and use of oxygen masks is

essential to ensure optimum performance during

routine flight operations and emergencies. The

aircrew member’s responsibility for maintenance

of the oxygen mask is limited to cleaning. Repairs

or other maintenance actions required are

performed at the organizational level or above.

PREFLIGHT/POSTFLIGHT

INSPECTION

The preflight/postflight inspection is a visual

inspection performed by the aircrew member to

4-31

whom the oxygen mask is issued before each

flight. The preflight/postflight inspection consists

of-the following-procedures:

NOTE: Defects or questionable areas

noted during this inspection must be

referred to the proper maintenance activity

for required corrective action.

1. Check the communication system and

microphone for proper installation.

2. Check the mask for damage and proper

operation by using the tester and/or aircraft

oxygen and communications system.

Calendar Inspection

The calendar inspection is conducted every 30

days at the organizational level and consists of

a visual inspection, a functional check, and a

thorough cleaning of the oxygen mask assembly.

Refer to NAVAIR 13-1-6.7 for visual inspection

and functional check procedures.

NOTE: If a discrepancy is noted, refer to

table 4-4 for guidance.

Cleaning Mask

To clean and sanitize the oxygen mask

facepiece and housing assembly, proceed as

follows:

Preferred solution. Make a 1 percent by weight

solution of cleaning compound (Detergent, Gen-

eral Purpose, MIL-D-1 6791, Type I) by adding

1/4 to 1/2 ounce (liquid) of the compound to 1

gallon of water.

CAUTION

WHEN THE FOLLOWING ALTER-

NATE CLEANING SOLUTION MUST

BE USED, ONLY THE LATHER FROM

T H E S O L U T I O N I S U S E D F O R

CLEANING. THIS PREVENTS UN-

DISSOLVED SOAP SOLUTION FROM

GETTING INTO THE VALVE.

Alternate solution. Make a suitable soap

solution by adding approximately 4 tablespoons

of soap powder (P-S-600) to 1 gallon of water.

Hardness of water may require more soap, but

the solution must be sufficiently strong to readily

form lather when agitated. Make sure that all soap

particles are dissolved.