9. Check that system components perform

reverses the action of both blades. The mechanical

smoothly with no erratic operation and blade reversing

locking device is provided to hold the blades in the

is synchronized. Blade rotation must be 75 degrees.

parked position when the needle valve is closed.

The wiper blades must not touch the center post, travel

NOTE: Do not operate the windshield wiper

into the parking area, or short cycle during high-speed

blades on a dry windshield.

operation.

Maintenance of the windshield wiper system

10. Reduce speed of blade operation, and manually

consists mainly of operational checks, removal and

stall each wiper separately. While the blade is stalled,

installation of components, and troubleshooting.

the opposite blade should operate smoothly.

11. Park the blades by slowing down the cycling

The operational check should be performed

speed to permit blades to move into the park position

according to the following procedures:

before they reverse.

1. Provide a supply of water on the outside

NOTE: Parking area is the area between the bottom

surface of the panels when the wiper blades are in

edge of the glass and the break in the contour of the

motion.

fuselage. To adjust the blades, loosen the blade

2. Check for a wiper arm force of 7 to 10 pounds

attaching screw and rotate blade. One serration is

on the windshield (at the blade attachment).

approximately 5 degrees of rotation. If it is not possible

3. Connect external electrical power supply.

to install within the parking area, install the arm

4. Energize hydraulic power system No. 1 ac

outboard with the blades as close to the parking area as

pumps.

possible, then remove the arm and adapter. Looking

5. Slowly open the windshield wiper speed

down on the arm, carefully remove the adapter and

control needle valve.

rotate it one serration counterclockwise with respect to

6. Blades must move from parked position and

the arm, and then reinstall the adapter in the arm. This

begin to cycle between 100 to 300 strokes per minute.

will permit the arm to be installed approximately 1.25

7. Open instrument panel to gain access to

inches closer to the parking area. If the blade is still

window units. Bleed air from units as they cycle by

parked on the glass, repeat the above procedure. Final

cracking the B-nuts on the tubing at each end of the

adjustment must leave slots in the adapter and arm

window units. Allow fluid to bleed into existing drip

approximately in line to permit proper clamping action

pans until it is evident that all air has been removed.

of the arm and adapter to the shaft of the window unit.

8. Check that no hydraulic fluid leak is visible on

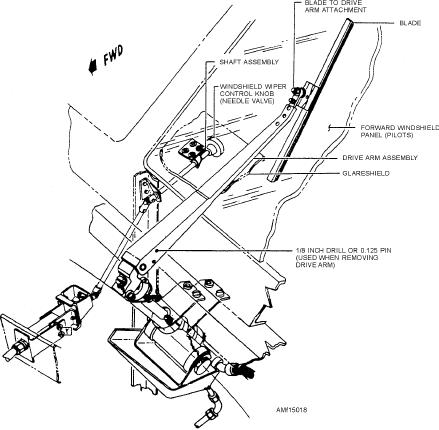

Figure 15-18 illustrates a windshield wiper unit.

the system tubing, connections, or at any component.

Figure 15-18.--Windshield wiper unit.

15-20