Q15-21. During normal aircraft operation, the

copilot's sub-instrument panel operates the shutoff

hydraulically operated generator drive

valve that controls the generator drive system. The

system AC GEN switch is OFF, and the

system consists of a shutoff valve, a hydraulically

solenoid-operated shutoff valve is energized

driven motor, a heat exchanger, a control switch, and a

(closed). What other component is also

relay.

energized?

During normal aircraft operation and with the AC

GEN switch at OFF, the solenoid-operated shutoff

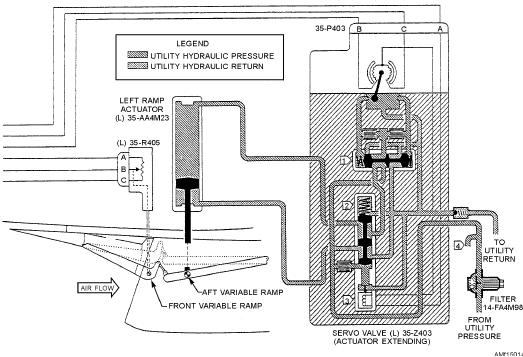

VARIABLE RAMP AND BELLMOUTH

valve is energized (closed). The hydraulic motor

SYSTEMS

lockout relay is also energized. Under this condition,

the generator does not operate, since hydraulic pressure

LEARNING OBJECTIVES: Recognize the

is stopped at the shutoff valve. When the AC GEN

characteristics of the variable ramp and

switch is moved to ON, the hydraulic motor lockout

bellmouth systems. Identify their components

relay and the shutoff valve is de-energized and the valve

and applicable maintenance requirements.

opens. Hydraulic fluid at 3,000 psi is directed to operate

The airflow velocities encountered in the higher

the constant speed variable displacement motor at

speed ranges of aircraft are much higher than the engine

8,000 rpm. When the fluid exits from the motor into the

can efficiently use. Therefore, the air velocity must be

return lines, it is routed through a heat exchanger and

controlled for acceptable engine performance.

ram air cooled before returning to the power system

reservoir. When ram air is not available on the deck, an

The variable inlet ramp system positions the inlet

electrically driven blower is engaged automatically to

ramp (located in the air inlet) so that it will position the

provide airflow.

shock wave to decrease the inlet air velocity to a

subsonic flow with maximum pressure energy. The

Maintenance of the generator drive system nor-

system also provides for the reflection and bypass of

mally consists of servicing, testing and checking for

surplus air not required by the engine with a minimum

proper operation, adjusting, troubleshooting, and

of drag. The inlet system in combination with the

removal and installation of system components,

bypass bellmouth system allows the inlet duct to take

flexible line couplings, and other plumbing. Servicing

aboard the maximum free airstream. The air not

and maintenance procedures and precautions are listed

required by the engine is bypassed by the action of the

in the MIM and respective (03) overhaul manuals and

bellmouth ring.

must be observed at all times to complete the

procedures efficiently and safely. Particular attention

Figure 15-14 shows the ramp sections and

should be given to cautions and warnings and specified

associated hydraulic mechanism and linkage. The aft

quality assurance considerations.

Figure 15-14.--Ramp servo and actuator.

15-16