components that are to be installed immediately

Step-by-step procedures for the repair of

subsequent to bench testing should be drip-drained,

components are provided in the "Intermediate

capped, and plugged as necessary. Plastic plugs are

Maintenance" section of some MIMs and/or 03

prohibited because of the possibility of plastic chips

manuals. In general, repairs will consist of cleaning,

entering the component and damaging seals or

disassembly, inspection, and replacement of failed

blocking critical passages.

parts, reassembly, and testing.

The man-hours expended in correcting malfunc-

Inspection of disassembled components includes

tions are documented on a VIDS/MAF. When a part is

checking for visible damage to internal parts, thread

removed and is to be processed through the IMA for

damage, condition of plating, wear limitations, spring

repairs, an additional VIDS/MAF is initiated with the

distortion, specified free length of spring, and

appropriate information filled in and attached to the

corrosion. In some cases, nondestructive inspection of

component for turn-in. Consult the appropriate man-

critical parts to detect discontinuities and fatigue cracks

uals for proper documentation of the VIDS/MAF. The

is required.

job is not considered complete until the necessary paper-

Reassembly will normally be in the reverse order of

work has been completed, screened, and turned in.

disassembly and will include proper installation of

Q15-19. What component is installed in the pressure

parts, seals, packings, retainers, torquing, safety

line of the wing fold and wing lock selector

wiring, and cotter keying, as applicable. Test of the

valves to vent excessive pressure buildup

component following repair will further verify its

because of thermal expansion of trapped fluid

ability to perform its intended function and will

into the combined system return lines?

generally consist of proof testing, static leak testing,

and operational testing.

Q15-20. Wing lock warning flags rarely get out of

adjustment; however, when one fails to

Throughout the complete intermediate level repair

retract, what does it indicate?

operation, the components undergoing repair must be

subjected to quality assurance verification of specified

repair steps as indicated in the applicable MIM or (03)

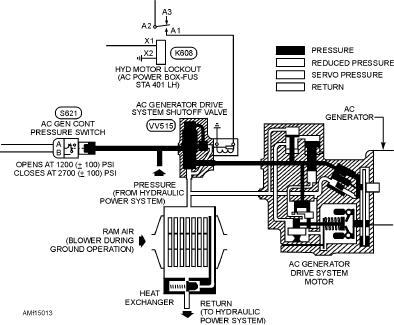

GENERATOR DRIVE SYSTEM

overhaul manual. It is NOT sufficient to eliminate the

(HYDRAULICALLY OPERATED)

progressive quality assurance and verify the operation

LEARNING OBJECTIVES: Identify the

of the end product.

types of generator drive systems. Identify their

Stationary test benches used for testing hydraulic

components and applicable maintenance re-

components are filled with preservative hydraulic fluid.

quirements.

Repaired components that are not to be installed

The ac generator drive system shown in figure

immediately must be filled with MIL-H-46170 unless

15-13 is hydraulically operated by pressure from the

otherwise specified. All openings are capped or

hydraulic power system. The AC GEN switch on the

plugged with approved metal closures. Repaired

Figure 15-13.--AC generator drive system.

15-15