originating in the aircraft drive shaft. It will also

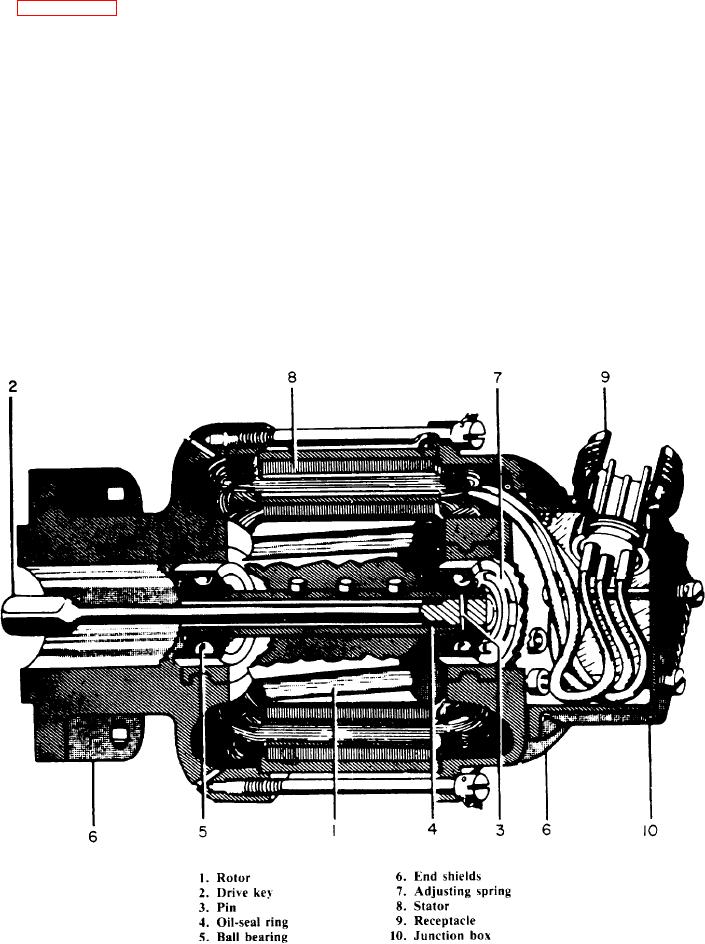

Figure 6-44 shows a cutaway view of a

accommodate small misalignments between the

tachometer generator. You should refer to it while

generator and its mounting surfaces. This key goes

you read this section. The generator consists

into the hollow rotor shaft. A pin (callout 3) at

essentially of a permanent-magnet rotor (callout

the end opposite the drive shaft secures the key

1) and a stator (callout 8) that develop three-phase

in place. An oil-seal ring (callout 4) is located

power as the rotor turns.

inside the hollow shaft and over this key. This seal

The armature of the generator consists of a

prevents oil from leaking into the generator

magnetized rotor. The rotor is cast directly onto

through the hollow shaft. The shaft runs in two

the generator shaft. The generator may be of

ball bearings (callout 5) set in stainless steel inserts.

either two- or four-pole construction. The two-

The inserts are cast directly into the generator end

and four-pole rotors are identical in appearance

shields (callout 6). An adjusting spring (callout

and construction. They differ in that the two-pole

7) at the receptacle end of the shaft maintains the

rotor is magnetized north and south diametrically

proper amount of end play.

across the rotor, while the four-pole rotor is

The stator consists of a steel ring with a

magnetized alternately north and south at each

laminated core of ferromagnetic material. A

of the four pole faces.

three-phase winding goes around this core and is

The key (callout 2) that drives the rotor is a

insulated from it. The winding is adapted for

long, slender shaft. It has enough flexibility to

two- or four-pole construction, depending on the

prevent failure under the torsional oscillations

Figure 6-44.-Cutaway view of a tachometer generator.

6-40