generator in which it is used. The two end shields

motion of the permanent magnet rotor. The

are of die-cast aluminum alloy. They serve to

spring is secured to the shaft to transmit torque

support the generator stator and rotor by means

from the rotor to the shaft. Ball bearings in the

of a receptacle (callout 9). The receptacle attaches

motor end shields support the shaft. These end

to the junction box (callout 10) of the generator.

shields also serve to locate the stator. This lets all

parts of the motor maintain their proper position

Tachometer Indicators

with respect to each other.

The armature of the synchronous motor

Tachometer indicators mount on the cockpit

consists mainly of the permanent magnet and the

instrument panel. They are relatively small in size.

hysteresis disk. The purpose of the permanent-

The type of unit varies. Depending on the

magnet material is to provide starting and running

particular installation, some are single element

torque at low speeds. The hysteresis disk provides

and others are dual element, The operating

starting torque at high speed. This is necessary

principles of the two types are basically the same.

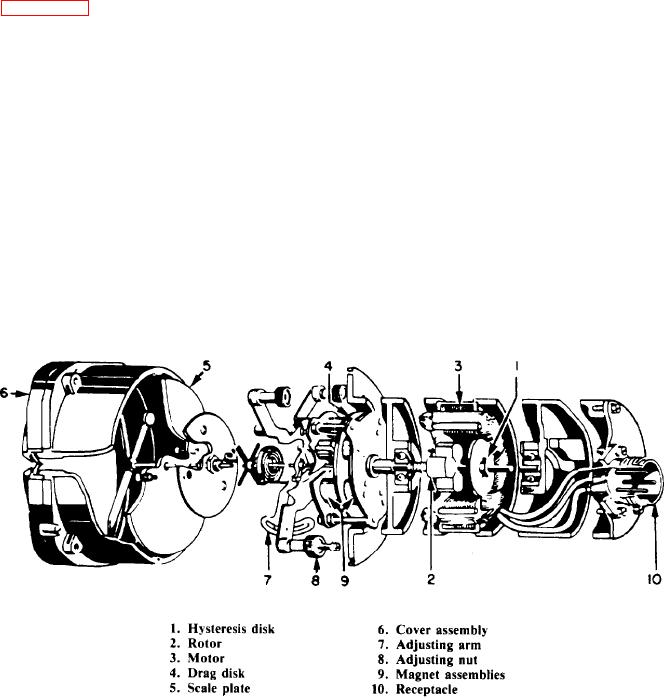

Figure 6-45 shows a cutaway view of a single-

permanent magnet, by itself, cannot pull into step.

element tachometer (radial) indicator. The unit

At the higher speeds, the hysteresis disk moves

consists essentially of two parts a synchronous

the rotor up to near synchronism, and then the

motor and an indicating element. The motor runs

permanent magnet pulls it into exact synchronism.

in synchronism with the tachometer generator. It

One end of the motor shaft extends through

also drives the indicating element through a

the front end shield and supports the drag-magnet

magnetic-drag coupling. The indicating element

assembly (callout 9). The drag-magnet assembly,

indicates the speed of the synchronous motor,

which is driven by the synchronous motor,

and, therefore, the speed of the aircraft engine.

consists of two plates to which small permanent

The synchronous motor (callout 3) consists of

magnets attach. The arrangement of the magnets

a three-phase stator winding that goes in, and is

concentrate the flux near the outside edge of the

insulated from, a laminated circular core. Within

drag disk. This arrangement obtains maximum

the circular core is a shaft. The rotating parts

torque with minimum weight. Between the two,

attach to this shaft. A cotter pin secures a

plates carrying the magnets is a disk (callout 4)

hysteresis disk (callout 1) to the shaft. A

of conducting material. This material is an alloy

permanent magnet rotor (callout 2) is free to move

having a low-temperature coefficient. This

on the shaft. The hysteresis disk at one shaft end

prevents temperature changes from affecting the

and a spring at the other restrain longitudinal

material's resistance. The magnet assembly

Figure 6-45.-Cutaway view of a tachometer indicator (radial).