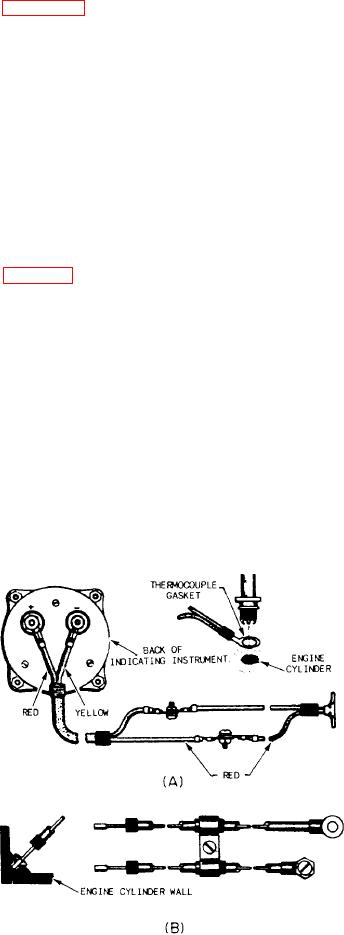

figure 6-50. In the gasket thermocouple, the rings

the thermocouple harness terminal block to the

indicator. Plugs in the thermocouple circuits are

of two dissimilar metals are pressed together,

forming a spark plug gasket. Each lead that

also of a special type. The thermocouple harness

mounts on the turbine unit aft of the thermo-

connects back to the galvanometers must be of the

couple. The harness includes separate leads for

same metal as the thermocouple part to which it

connects. For example, a copper wire connects to

each of the 18 thermocouples, and it maintains

the copper ring, and a constantan wire connects

two electrically separate circuits. The harness is

located inside a rigid metal, channel type of

to the constantan ring. Thermocouple leads are

housing and cover. The leads and terminals

critical in makeup and length because the

project through holes in the front side of the

galvanometers are calibrated for a specific set of

leads in the circuits.

housing wall. Electrical signals from the 18

dual-junction thermocouples are averaged within

the harness.

TURBINE INLET TEMPERATURE (TIT)

The thermocouple assemblies mount on pads

INDICATOR SYSTEM. --Some aircraft have an

provided around the turbine inlet case. Each

engine turbine inlet temperature indicator system

(fig. 6-51) to provide a visual indication of

thermocouple incorporates two electrically

independent junctions within a sampling type

temperatures entering the turbine. The tempera-

probe. AL identifies Alumel terminal studs, and

ture of each engine turbine inlet is measured by

CR identifies Chromel terminal studs.

18 dual-unit thermocouples in the turbine inlet

Since the average voltage of the thermocouples

casing. These dual thermocouples are connected

in parallel. One set sends signals through a harness

at the thermocouple terminal blocks represents the

and aircraft wiring to an indicator. The other

turbine inlet temperature, it is necessary that no

interference with the signal take place while the

set of thermocouples provides signals to the

signal goes to the indicator. Therefore, the wiring

temperature datum control. Each circuit is

from the thermocouple terminal block to the

electrically independent and provides dual system

dependability.

indicator goes through the harness. The harness

wiring goes separately from other interference-

All parts of the engine temperature measure-

producing wiring.

ment system are made of Chromel and Alumel

The indicator contains a bridge circuit with

material, including welds. Special wiring and

wire identification are in the aircraft from

cold junction compensation, a two-phase motor

to drive the pointer, and a feedback potenti-

ometer. Also included in the indicator is the Zener

voltage reference circuit, a chopper circuit, an

amplifier, power supply, a power-off flag, and

an overtemp warning light.

Output of the bridge circuit goes to the

chopper circuit, so the bridge circuit isn't loaded.

The chopper output goes to the amplifier. Output

of the amplifier feeds the variable field of

a two-phase motor. This field positions the

indicator main pointer and the digital indicator,

The motor also drives the feedback potentiometer

to provide a nulling signal. The signal is relative

to the temperature signal and stops the drive

motor upon reaching the correct pointer position.

The Zener diode circuit protides a closely

regulated reference voltage in the bridge, This

signal avoids the error caused by voltage variation

from the indicator power supply. The indicator

power supply powers the Zener circuit, the

chopper, and the amplifier. It also powers the

power off warning flag and the fixed field of the

two-phase motor.

The overtemperature warning light in the

indicator comes on when the turbine inlet

Figure 6-50.-Thermocouples: (A) gasket type; (B) rivet type.

6-46