parallel. The harness mounts on the turbine frame

aft of the turbine rotor.

FUEL FLOW SYSTEMS

Fuel flow indicating systems provide a con-

tinuous indication of the rate of fuel delivery to

the engine. The rate of flow is in pounds per hour.

In some systems, the indicator also shows the

amount of fuel remaining in the tanks. A typical

flowmeter consists of two units--a transmitter

and an indicator. The measurements are trans-

mitted electrically to the panel-mounted indicator.

Thus, use of electrical transmission ends the need

for a direct fuel-filled line from the engine to the

instrument panel. This minimizes the chance of

fire and reduces mechanical failure rate.

The fuel flowmeter system is quite similar

to other synchro systems discussed in Navy

Electricity and Electronics Training Series

(NEETS) course. The following discussion

describes a typical fuel flow indicating system

to acquaint you with flowmeters in general.

However, you should always refer to the manuals

for the particular system you are maintaining.

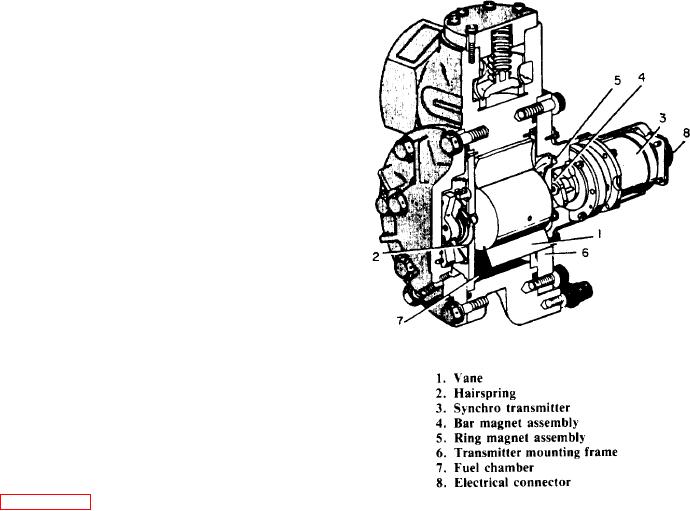

Fuel Flow Transmitter

Figure 6-53 shows a cutaway view of a fuel

Figure 6-53.-Cutaway view of a fuel flow transmitter.

flow transmitter. It is a two-in-one unit--a

fuel-measuring mechanism (or meter) and a

synchro transmitter. You can separate these parts

the bar magnet. The two magnets send vane

from one another for maintenance purposes, but

movement, caused by the fuel flow, to the synchro

they join as a single assembly for installation.

rotor. This action results in a corresponding

The fuel enters the inlet port of the transmitter

movement of the rotor. Therefore, the angular

and flows against the vane (callout 1), causing the

displacement of the vane in relation to the fuel

vane to swing. The spiral fuel chamber design

chamber housing determines the synchro rotor

allows the distance between the vane and chamber

movement with respect to the stator.

wall to become increasingly larger as fuel flow

The fuel flow transmitter has a relief valve,

increases. A calibrated hairspring (callout 2)

which automatically opens and bypasses the

retards the motion of the vane. The vane ceases

instrument when the fuel flow exceeds the capacity

motion when the forces exerted on it by the

of the instrument. At such time, only part of the

hairspring and by the fuel are equal.

fuel flows through the metering portion. As the

The rotor shaft of the synchro transmitter

pressure across the instrument falls below the

(callout 3) connects to a bar magnet (callout 4).

value at which the relief valve opens, the valve

Attached to the vane shaft is a ring magnet

closes. This lets the flowmeter again operate

(callout 5). The ring magnet moves as the vane

normally. The transmitter unit location is in the

shaft moves. The transmitter mounting frame is

fuel line between the fuel pump and fuel nozzle.

between the bar magnet and the ring magnet,

forming a liquid-tight seal. This is the seal between

Fuel Flow Indicator

the fuel-metering section of the mechanism and

the synchro. However, the bar magnet moves in

The fuel flowmeter indicator is located on the

unison with the ring magnet because the two

instrument panel. It is a remote-indicating

magnets are magnetically coupled. The south pole

instrument. This indicator consists of a synchro

of the ring magnet is opposite the north pole of