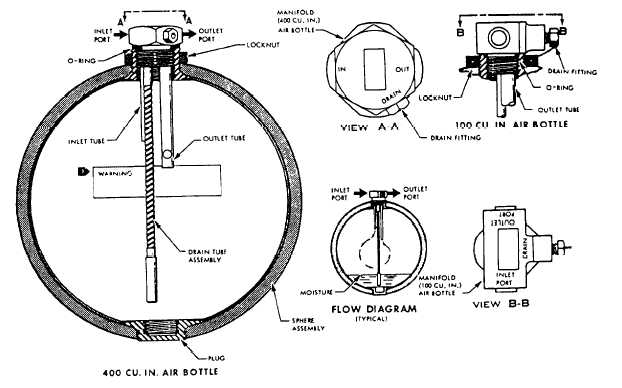

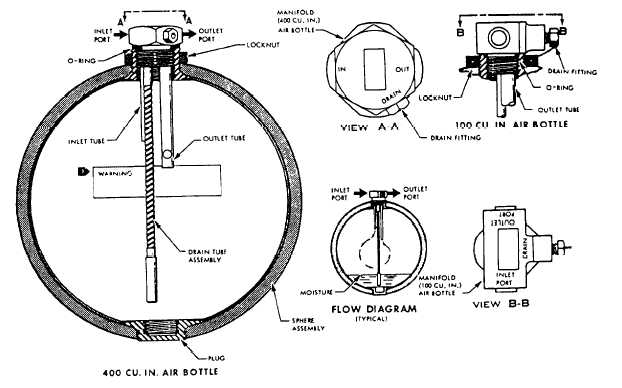

Figure 7-44.—Air cylinder.

cylindrical or spherical in shape. Both types of

cylinders are made up of two main parts—the

container itself and a manifold assembly. The

container serves as a trap for moisture, as well as an

air storage space. The manifold assembly is made up

of the “in” and “outlet” ports and a moisture drain

fitting. See figure 7-44.

Cooling of the high-pressure air in the storage

cylinders will cause some condensation to collect in

them. To ensure positive operation of systems,

storage cylinders must be purged of moisture

periodically. This is accomplished by slightly

cracking the moisture drain fitting, located on the

cylinder manifold.

Some aircraft have a pneumatic system that will

maintain the required pressure in these bottles in

flight. However, most of these pneumatic systems

require servicing on the ground with an external

source of high-pressure air or nitrogen prior to each

flight.

Air storage bottles are serviced in the same

manner as accumulators. Most air bottles have an air

filler valve and a pressure gauge. These systems

generally require higher servicing pressure than

accumulators.

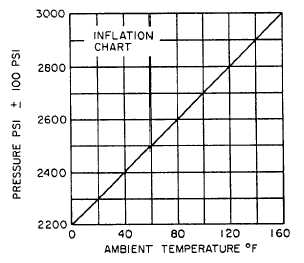

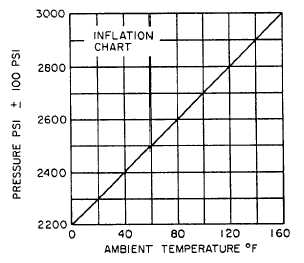

Since gases expand with heat and contract when

cooled, air storage bottles are usually filled to a given

pressure at ambient temperature. A graph similar to

that shown in figure 7-45 is usually mounted on a

Figure 7-45.—Pneumatic storage cylinder inflation chart.

7-45