and a hydraulic pressure selector switch and dual

pointer indicator, both located on the pilot’s

instrument panel.

The transmitters operate on the Bourdon tube

principle. Expansion and contraction of the Bourdon

tube is transmitted by mechanical linkage to the rotor

of a transmitter synchro. The synchro transmits an

electrical signal through wiring to the pressure

indicator. The indicator contains two synchros

mechanically attached to the two separate pointers.

When the HYD PRESS SELECTOR switch (fig.

7-37) is in the No. 1 and No. 2 FLT CONT position,

the pointers (marked "1" and "2") indicate the

pressure in their respective systems, independent of

each other. When the HYD PRESS SELECTOR

switch is in the UTILITY position, the synchros are

connected in electrical parallel, and the pointers align

with each other and act as one.

Although the Aviation Electrician’s Mate is

responsible for inspecting and maintaining all the

aircraft gauges and other instruments, you must know

how to read the hydraulic pressure gauge to inspect

and maintain the hydraulic system.

Pressure gauges on some naval aircraft are

calibrated to register from 0 to 2,000 psi; on others

they register from 0 to 4,000 psi. The gauge in

figure 7-37 is an example of the latter type.

As shown in figure 7-37, on gauges designed for

a range of 0 to 4,000 psi, the dial is calibrated with

four major markings with the numerals 1,2,3, and 4.

One major intermediate graduation between each

numeral and four minor intermediate markings

between the major markings are for reading to the

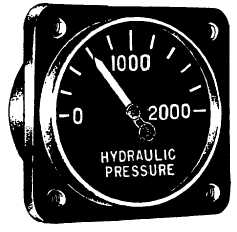

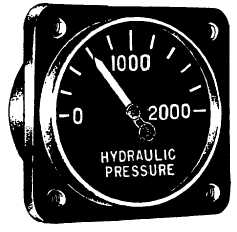

Figure 7-38.—Hydraulic pressure gauge.

nearest 100 psi.

On these gauges, the numeral

reading must be multiplied by 1,000 to obtain the

actual pressure in psi.

On gauges designed for a range of 0 to 2,000 psi,

the dial is calibrated with two major markings, the

numerals 1,000 and 2,000, and four intermediate

graduations for reading to the nearest 200 psi. A

gauge of this type is shown in figure 7-38.

GAUGE AND PRESSURE TRANSMITTER

SNUBBERS

A gauge and pressure transmitter snubber is a

hydraulic component located upstream of pressure

gauges and pressure transmitters. Its purpose is to

damper out system pressure surges that could cause

possible damage to gauges and pressure transmitters.

Snubbers also prevent cockpit hydraulic indicators

from oscillating and fluctuating, which makes

accurate reading of the gauge not only difficult but

often impossible.

Without the use of a snubber,

pressure oscillations and other sudden pressure

changes existing in hydraulic systems could affect the

delicate internal mechanism of both gauges and

transmitters.

This may cause either complete

destruction of the gauge or transmitter or, often

worse, partial damage, resulting in false readings.

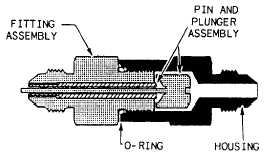

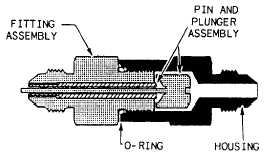

The basic components of a snubber are the

housing, fitting assembly with a fixed orifice

diameter, and the pin and plunger assembly, as shown

in figure 7-39. The snubbing action is obtained by

metering fluid through the snubber.

The fitting

assembly orifice restricts the amount of fluid that

flows to the gauge or pressure transmitter, thereby

snubbing the force of a pressure surge. The pin is

pushed and pulled through the orifice of the fitting

assembly by the plunger, keeping it clear and at a

uniform size.

Figure 7-39.—Gauge and pressure transmitter snubber.

7-40