perform the same function—that of storing an extra

volume of hydraulic fluid under pressure.

Maintenance

Accumulators should be visually examined for

indications of external hydraulic fluid leaks. They

should then be examined for external air leaks by

brushing the exterior with soapy water, which will

form bubbles where the air leaks occur.

The air valve assembly should be loosened to

examine the accumulator for internal leaks. If

hydraulic fluid comes out of the air valve, the

accumulator should be removed and replaced. The

overhaul or repair of the accumulator is not a line

maintenance function, but it is the responsibility of an

intermediate-level activity.

The air preload pressure should be checked after

relieving the hydraulic system pressure by operating

the wing flaps or other hydraulically actuated unit.

The majority of the accumulators installed in naval

aircraft are equipped with air pressure gauges for this

purpose. When the accumulator is not equipped with

a high-pressure air gauge, you may install one at the

air preload fitting for this purpose. The required

pressure can be found in the MIM for each aircraft.

The preload pressure may be checked by another

method in case the accumulator is not equipped with

an air pressure gauge. With the system pressure (as

indicated by the cockpit gauge) at the normal

operating value, relieve system pressure by operating

the wing flaps or another unit slowly. The pressure

gauge reading must be watched carefully. The last

reading before the indicator needle drops suddenly to

zero is accepted as the accumulator preload air

pressure.

Before disassembly of any accumulator, ensure

that the air preload has been completely exhausted.

This may be accomplished by loosening the swivel

nut on the air filler valve until all air is out; then

remove the valve.

Servicing

The purpose of the hydraulic system accumulator

is to store an extra volume of fluid under pressure.

The energy stored in an accumulator is used for

various purposes, such as the actuation of a unit in the

event of normal hydraulic system failure. For

example, sufficient energy can be stored in an

accumulator for several applications of the wheel

brakes.

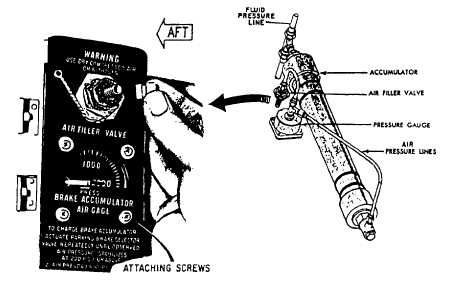

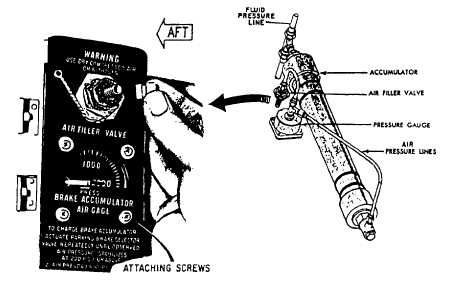

Most accumulators are installed with an air gauge

and a high-pressure air valve mounted on a panel of

the structure near the accumulator.

Figure 7-35

shows the brake system accumulator installation used

on one type of aircraft.

The air valve used in the

accumulator installations is usually the same type as

that used on shock struts.

Figure 7-35.—Accumulator air charge valve and gauge installation.

7-38