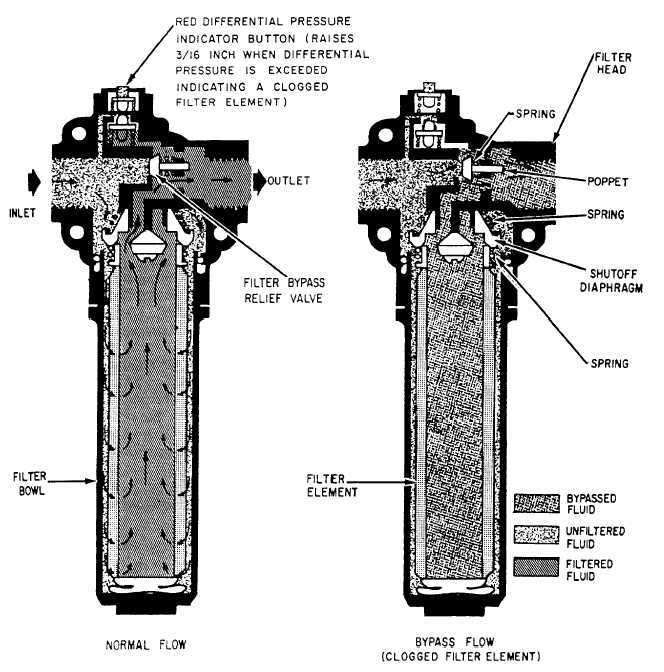

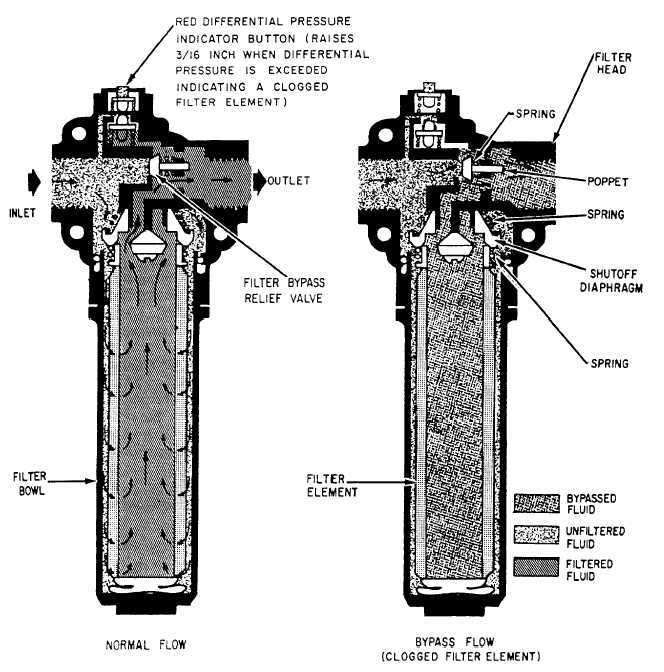

Differential Pressure Indicators

The extent to which a filter element is loaded can

be determined by measuring the drop in hydraulic

pressure across the element under rated flow

conditions.

This drop or “differential pressure”

provides a convenient means of monitoring the

condition of installed filter elements, and is the

operating principle used in the differential-pressure or

loaded-filter indicators found on many filter

assemblies. Differential pressure indicating devices

have many configurations, including electrical

switches, continuous-reading visual indicators

(gauges), and visual indicators with memory. Visual

indicators with memory usually take the form of

magnetic or mechanically latched buttons or pins that

extend when the differential pressure exceeds that

allowed for a serviceable element. See figure 7-33.

When this increased pressure reaches a specific value,

inlet pressure forces the spring-loaded magnetic

Figure 7-33.—Hydraulic filter assembly incorporating differential pressure indicator.

7-34