reliability of the entire system depend upon adequate

filtration.

Continuous filtration of hydraulic fluid during

system operation is necessary to maintain system

cleanliness. You should use filters that have fine

pores or openings to allow hydraulic fluid to pass but

that are small enough to trap contaminant particles.

Hydraulic filter elements are rated in several ways.

The absolute filtration rating is the diameter in

microns of the largest spherical particle that will pass

through the filter under a certain test condition. This

rating is an indication of the largest opening in the

filter element. The mean filtration rating is the

measurement of the average size of the openings in

the filter element. The nominal filtration rating is

usually interpreted to mean the size of the smallest

particles of which 90 percent will be trapped in the

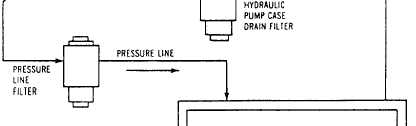

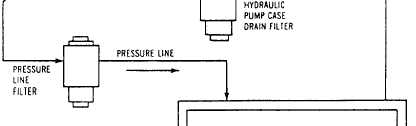

filter at each pass through the filter. Figure 7-31

shows a typical filter arrangement in a hydraulic

system.

Filters may be located within the reservoir, the

pressure line, the return line, or any other location

where they are needed to safeguard the hydraulic

system against contaminants. Their location in the

system and other design criteria determine their shape

and size.

Basic Units

The filter assembly is composed of three basic

units. The units are a head assembly, a bowl, and a

Figure 7-31.—Typical filter arrangement in hydraulic system.

7-32

filter element. See figure 7-32.