A three-way directional control valve is normally

used to control the operation of this type of cylinder.

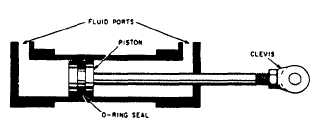

To extend the piston rod, fluid under pressure is

directed through the port and into the cylinder. See

figure 8-1. This pressure acts on the surface area of

the blank side of the piston, and forces the piston to

the right. This action, of course, extends the rod to the

right, through the end of the cylinder. The actuated

unit is moved in one direction. During this action, the

spring is compressed between the rod side of the

piston and the end of the cylinder. Within limits of the

cylinder, the length of the stroke depends upon the

desired movement of the actuated unit.

To retract the piston rod, the directional control

valve is moved to the opposite working position,

which releases the pressure in the cylinder. The

spring tension forces the piston to the left, retracting

the piston rod and moving the actuated unit in the

opposite direction. The fluid is free to flow from the

cylinder through the port, and back through the

control valve to return.

The end of the cylinder opposite the fluid port is

vented to the atmosphere. This prevents air from

being trapped in this area. Any trapped air would

compress during the extension stroke, creating excess

pressure on the rod side of the piston. This would

cause sluggish movement of the piston, and could

eventually cause a complete lock, preventing the fluid

pressure from moving the piston. Leakage between

the cylinder wall and the piston is prevented by seals.

Hydraulic components use seals or gaskets to prevent

leakage between static parts (nonmoving), such as a

valve body and a hydraulic line fitting. Seals also

prevent leakage between dynamic (moving) parts,

such as the piston and cylinder wall. The most

common seal is an O-ring. Some static seals and all

dynamic seals require a backup ring or rings.

Double-Acting Actuating Cylinder

Most piston-type actuating cylinders are

double-acting, which means that fluid under pressure

can be applied to either side of the piston to provide

movement and apply force in the corresponding

direction.

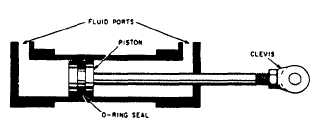

One design of the double-acting,

piston-type actuating cylinder is shown in view A of

figure 8-2. This cylinder contains one piston and

piston rod assembly. The stroke of the piston and

piston rod assembly in either direction is produced by

fluid pressure. The two fluid ports, one near each end

of the cylinder, alternate as inlet and outlet, depending

upon the “direction of flow from the directional control

valve.

This is referred to as an unbalanced actuating

cylinder; that is, there is a difference in the effective

working areas on the two sides of the piston. Refer to

view A of figure 8-2. Assume that the cross-sectional

area of the piston is 3 square inches and the

cross-sectional area of the rod is 1 square inch. In a

2,000 psi system, pressure acting against the blank

side of the piston creates a force of 6,000 pounds

(2,000 x 3). When the pressure is applied to the rod

side of the piston, the 2,000 psi pressure acts on

2 square inches (the cross-sectional area of the piston

less the cross-sectional area of the rod) and creates a

force of 4,000 pounds (2,000 x 2). For this reason,

this type of cylinder is normally installed in such a

manner that the blank side of the piston carries the

greater load; that is, the cylinder carries the greater

load during the piston rod extension stroke.

A four-way directional control valve is normally

used to control the operation of this type of cylinder.

The valve can be positioned to direct fluid under

pressure to either end of the cylinder, and to allow the

displaced fluid to flow from the opposite end of the

cylinder through the control valve to return/exhaust.

The piston of the cylinder shown in view A of

figure 8-2 is equipped with an O-ring seal and backup

rings to prevent internal leakage of fluid from one

side of the piston to the other. Suitable seals and

backup rings are also used between the hole in the end

cap and the piston rod to prevent external leakage. In

addition, some cylinders of this type have a felt wiper

ring attached to the inside of the end cap and fitted

around the piston rod to guard against the entrance of

dirt and other foreign matter into the cylinder.

The actuating cylinder shown in view B of figure

8-2 is a double-acting balanced type. The piston rod

(A) UNBALANCED

(B) BALANCED

Figure 8-2.—Double-acting, piston-type actuating cylinders.

8-2