determine how many of these operations are

necessary. Each step in the process must be

performed thoroughly, or subsequent polishing will

not remove scratches left by previous operations.

Sanding and buffing cause thickness variations in

the plastic around the scratch. If skillfully done, these

operations will cause only minor optical distortions,

which will not be serious in most applications.

Distortion may be reduced by gently polishing and

feathering a fairly large area around the scratch. In

critical optical sections, however, even minor

distortions may cause serious deviations in sighting.

Such sections, even though scratched, should not be

sanded or buffed. If necessary, these sections are

replaced.

SANDING.—Transparent plastics should never

be sanded unless absolutely necessary, and then only

when surface scratches, which may impair vision, are

too deep for buffing. When sanding is necessary, the

finest, smallest grit abrasive paper that will remove

the scratch or other defect should be used first.

Normally, you will never need abrasive paper coarser

than No. 320A; however, abrasive paper as coarse as

No. 240A may be used if the situation warrants. The

abrasive paper is wrapped around a felt-covered,

wooden or rubber block, and the defective area is

rubbed lightly, using plain water or water with a

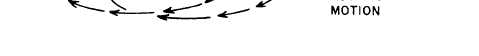

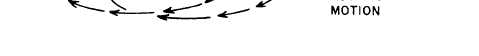

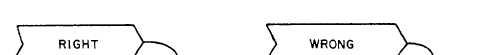

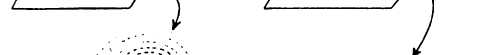

2-percent soap content as a lubricant. Use circular

strokes, as shown in figure 14-1. Never use a straight

back-and-forth motion. Sand an area about two or

three times the length of the defect in order to

minimize optical distortion and excessive thinning of

the plastic. The initial sanding should then be

followed by similar treatments, using successively

finer grades of sandpaper in the following sequence:

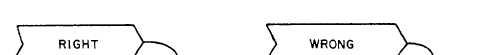

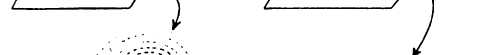

DO NOT SAND UNLESS ABSOLUTELY NECESSARY TO RE-

MOVE DEEP SCRATCHES.

HOLD SANDPAPER BY SMOOTH

RUBBER OR WOODEN BLOCK AND OVER A WIDE AREA

TO PREVENT OPTICAL DISTORTIONS.

EXCESS PRESSURE

IN SANDING OR BUFFING WILL BURN PLASTIC.

Figure 14-1.—Proper method of sanding plastic.

14-3