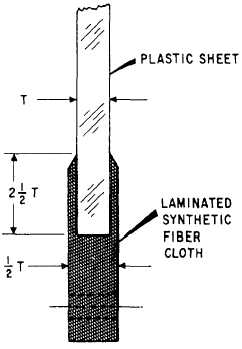

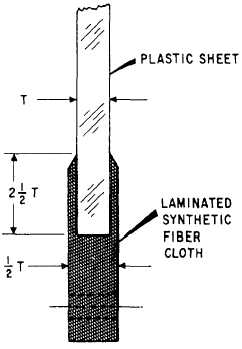

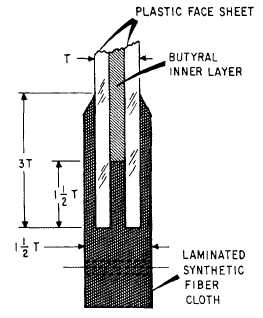

Figure 14-4.—Approved edge attachment for solid plastic.

hard and to which buffing compound is applied, is

used for removing the deeper scratches. The finish

wheel, which is soft, is then used to bring the plastic

to a high polish.

Both wheels are made up of

numerous layers of cloth discs, but the abrasive wheel

is made hard by several rows of stitches, as shown in

the illustration. The finish wheel is unstitched with

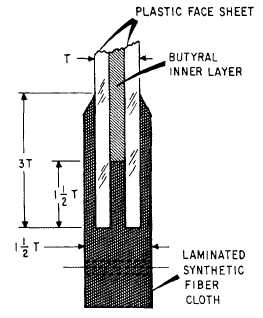

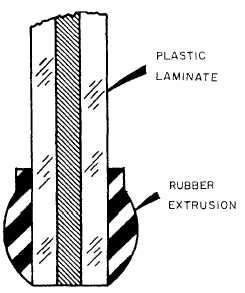

Figure 14-5.—Approved edge attachment for laminated

plastic.

spacers (washers) mounted between every fourth or

fifth cloth disc. Power for turning the buffing wheel

may be supplied by mounting it in a portable drill, as

shown in figure 14-3. At the start of each buffing

operation, the plastic must be clean and dry. Some of

the buffing compounds now available will leave the

surface clean so that washing is not necessary. Where

necessary, however, washing should follow each step

in buffing. If a panel has been sanded previously or is

deeply scratched, the abrasive wheel should be used

first. Apply fresh compound to the wheel and buff

lightly along and across all scratches. Keep the

plastic or wheel in motion to prevent generating too

much heat, thus damaging the plastic. Complete the

buffing operation by using the finish wheel, bringing

the plastic surface to a high gloss. After all scratches

have been removed with the finish wheel, a coat of

wax should be applied by hand.

CAUTION

Hand polishing is recommended in critical

vision areas.

Overheating transparent

plastic, by buffing, induces internal stresses

and optical distortions.

Installing Plastic Panels

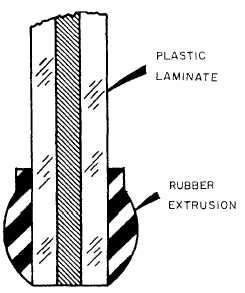

There are a number of methods for installing

transparent plastic panels in aircraft, some of which

are shown in figures 14-4 through 14-7. Which

Figure 14-6.—Typical sighting dome attachment.

14-5