components housing radar or radio gear must be made

in accordance with the manufacturer’s recom-

mendations. This information may be found in the

aircraft structural repair manual or in drawings and

specifications.

Before a thorough inspection of the damage can

be made, the area should be cleaned with a cloth

saturated with methyl ethyl ketone (MEK). After

drying, the paint should be removed by sanding

lightly with No. 280 grit sandpaper, and then clean the

sanded area with MEK. The extent of damage can

then be determined by tapping the suspected areas

with a blunt instrument. You could use a coin as a

blunt instrument, such as a quarter, to perform the tap

test. This is referred to as the “coin tap” method. You

should never use a hammer as a blunt instrument. The

damaged areas will have a dull or dead sound, while

the undamaged areas will have a clear metallic sound.

Damages are divided into four general classes:

surface damage, facing and core damage, puncture

damage (both facings and core), and damage

requiring replacement.

Repairing Surface Damage

The most common types of damage to the surface

are abrasions, scratches, scars, dents, cuts, and pits.

Minor surface damages may be repaired by applying

one or more coats of room-temperature catalyzed

resin to the damaged area. More severe damages may

be repaired by filling with a paste made from

room-temperature resin and short glass fibers. Over

this coated surface, apply a sheet of cellophane,

extending 2 or 3 inches beyond the repaired area.

After the cellophane is taped in place, start in the

center of the repair and lightly brush out all the air

bubbles and excessive resin with your hand or a

rubber squeegee towards the outer ridge of the repair.

Allow the resin to cure at room temperature, or if

necessary, the cure can be hastened by the use of

infrared lamps or hot sandbags. After the resin has

been cured, remove the cellophane and sand off the

excess resin; then, lightly sand the entire repaired area

to prepare it for refinishing.

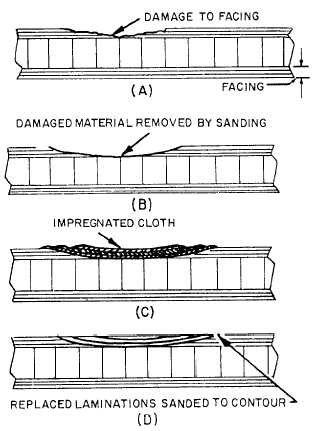

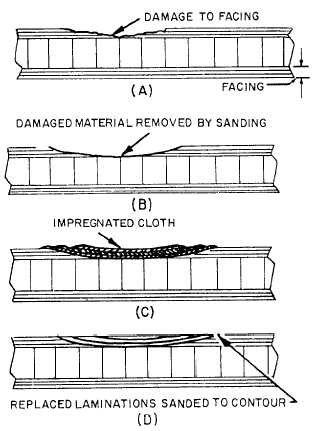

PLY DAMAGE (SANDWICH LAMI -

NATES).—When the damage has penetrated more

than one ply of the cloth in sandwich-type laminates,

the repair may be made by using the scarfed method,

shown in figure 14-8.

This repair is made in the

following manner:

Clean the area thoroughly, and

then sand out the damaged laminate plies, as shown in

view B. The area should be sanded to a circular or

oval shape, and then the area should be tapered

uniformly down to the deepest penetration of the

damage.

The diameter of the scarfed (tapered) area should

be at least 100 times the depth of the penetration. You

should exercise care when using a mechanical sander.

Excess pressure on the sander can cause the

sandpaper to grab, resulting in the delamination of

undamaged plies.

CAUTION

The sanding of glass cloth reinforced

laminates produces a fine dust that may

cause skin irritation. In addition, if you

breathe an excessive amount of this dust, it

may be injurious; precautions as to skin,

eyes, and respiration protection must be

observed.

Clean the area thoroughly, brush coat the sanded

area with one coat of room-temperature catalized

Figure 14-8.—Ply repair (scarfed method).

14-7