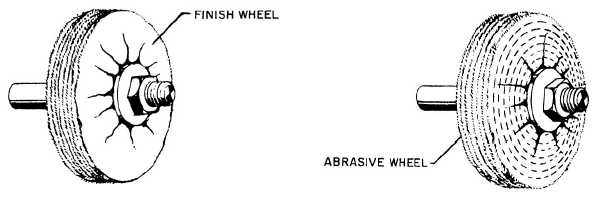

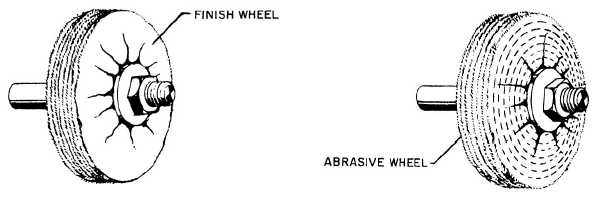

Figure 14-2.—Buffing wheels.

Nos. 400A, 500A, and 600A. Wash the plastic after

each operation. During each step, the deeper

scratches left by the preceding grade of abrasive

should be removed.

BUFFING.—To remove the fine, hairline

scratches caused by sanding, transparent plastic may

be buffed. It is often possible to remove scratches by

buffing alone, provided the scratches are not too deep.

There are a number of standard commercial

buffing

compounds

satisfactory

for

use

on

transparent plastic enclosures. They are usually

composed very fine alumina or similar abrasive in

combination with wax, tallow, or grease binders.

They are available in the form of bars or tubes for

convenience in applying to the buffing wheel.

Plain tallow is often applied to the buffing wheel.

It may be used in addition to buffing compound, or it

may be used alone. In the latter case, tallow functions

similar to wax as it fills in hairline scratches and

gives a high gloss to the surface.

Buffing wheels are made of cotton cloth or felt. For

removing scratches caused by sanding, an of

“abrasive” wheel and a “finish” wheel are needed (fig.

14-2). The abrasive wheel, which is relatively

217.162

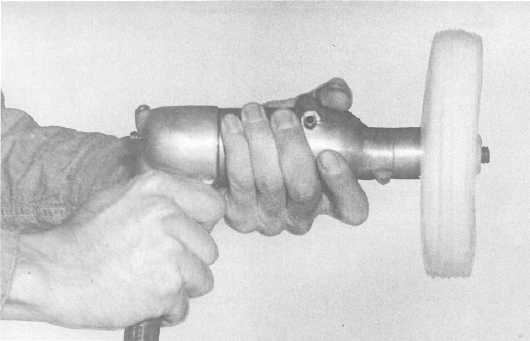

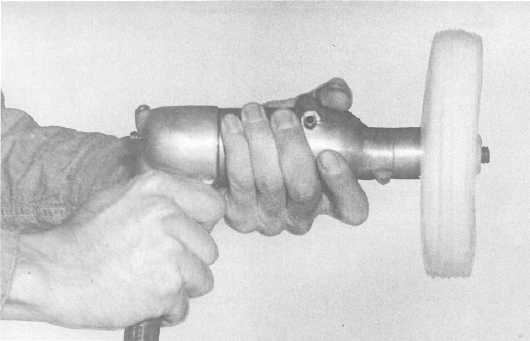

Figure 14-3.—Buffing wheel mounted in portable drill.

14-4