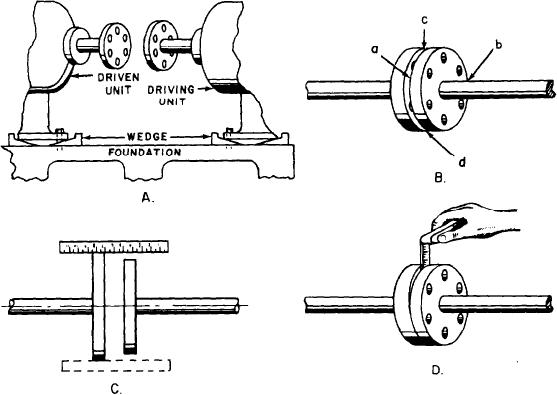

fastened, the units are securely bolted to the

manufacturer. If the misalignment is excessive,

foundation, and the coupling flanges are bolted

the coupling parts are subjected to severe punish-

together.

ment, necessitating frequent replacement of pins,

The faces of the coupling flanges should be

bushings, and bearings. It is absolutely necessary

checked at 90-degree intervals. This method is

to have the rotating shafts of the driving and

shown in figure 7-16, view B. Find the distances

driven units in proper alignment. Figure 7-16

between the faces at point a, point b (on the

shows coupling alignment.

opposite side), point c, and point d (opposite point

You should check the shaft alignment when

c). This action will show whether the coupling

the pump is opened for repair or maintenance,

faces are parallel to each other. If they are not

or if a noticeable vibration occurs. You must

parallel to each other, adjust the driving unit or

realign the unit if the shafts are out of line or

the pump with shims until the couplings check

inclined at an angle to each other. Whenever

true. While measuring the distances, you must

practicable, check the alignment with all piping

keep the outside diameters of the coupling flanges

in place and with the adjacent tanks and piping

in line. To do this, place the scale across the two

filled.

flanges, as shown in figure 7-16, view C. If the

When the driving unit is connected to the

flanges do not line up, raise or lower one of the

pump by a FLANGE COUPLING, the shafting

units with shims, or shift them sideways.

may require frequent realignment, which may be

The procedure for using a thickness gauge to

indicated by high temperatures, noises, and worn

check alignments is similar to that for a scale.

bearings or bushings.

When the outside diameters of the coupling

Wedges, or shims, are sometimes placed under

the bases of both the driven and driving units (fig.

flanges are not the same, use a scale on the

surface of the larger flange, and then use a

7-16, view A) for ease in alignment when the

thickness gauge between the surface of the smaller

machinery is installed. When the wedges or other

flange and the edge of the scale. When the

packing have been adjusted so the outside

space is narrow, check the distance between the

diameters and faces of the coupling flanges run

coupling flanges with a thickness gauge, as shown

true as they are manually revolved, the chocks are

Figure 7-16.--Coupling alignment.

7-12