necessary information on disassembly of the unit,

following table is a description of some of the

dimensions of the wearing rings, and reassembly

problems you will have to deal with together with

of the pump is specified by PMS or can be found

the probable causes:

in the manufacturer's technical manual. Failure

to replace the casing wearing ring when the

allowable clearance is exceeded results in a

decrease of pump capacity and efficiency. If you

have to disassemble a pump because of some

internal trouble, check the wearing ring for

clearance. Measure the outside diameter of the

impeller hub with an outside micrometer and the

inside diameter of the casing wearing ring with an

inside micrometer; the difference between the two

diameters is the actual wearing ring diametric

clearance. By checking the actual wearing ring

clearance with the maximum allowable clearance,

you can decide whether to renew the ring before

reassembling the pump. The applicable MRCs are

a readily available source of information on

proper clearances.

Wearing rings for most small pumps are

carried aboard ship as part of the ship's repair

parts allowance. These may need only a slight

amount of machining before they can be installed.

For some pumps, spare rotors are carried aboard

ship. The new rotor can be installed and the old

rotor sent to a repair activity for overhaul.

Overhauling a rotor includes renewing the wearing

rings, bearings, and shaft sleeve.

Operating Troubles.--You will be responsible

for the maintenance of centrifugal pumps. The

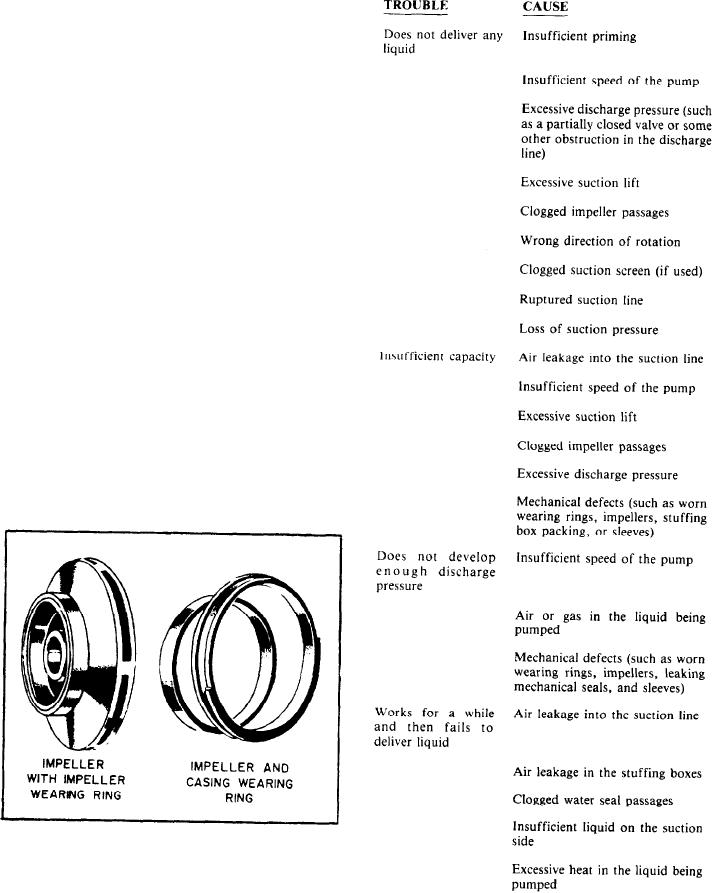

Figure 7-7.--Impeller, impeller wearing ring, and casing

wearing ring for a centrifugal pump.

7-7