can be installed. On others, the shaft sleeve may

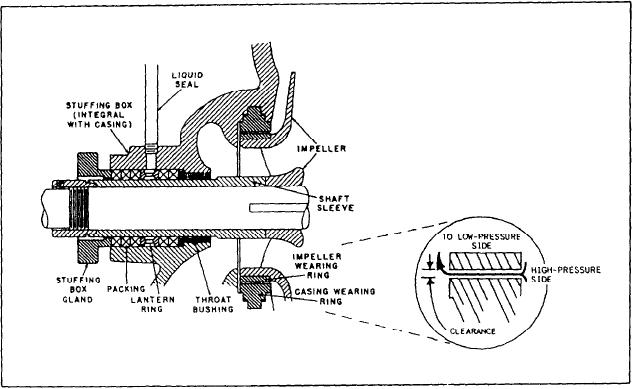

The packing in centrifugal pump stuffing

have a snug slip-on fit, butted up against a

boxes (fig. 7-6) is renewed following the PMS.

shoulder on the shaft and held securely in place

When replacing packing, be sure to use packing

with a nut. On smaller pumps, you can install new

of the specified material and the correct size.

sleeves by removing the water end casing,

Stagger the joints in the packing rings so they fall

impeller, and old shaft sleeves. New sleeves are

at different points around the shaft. Pack the

carried as repair parts; they can also be made in

stuffing box loosely and set up lightly on the

the machine shop. On a large pump, the sleeve

gland, allowing a liberal leakage. With the pump

is usually pressed on; the old sleeve must be

in operation, tighten the glands and gradually

machined off before a new one can be pressed on.

compress the packing. It is important to do this

You must disassemble the pump and take the

gradually and evenly to avoid excessive friction.

sleeve to a machine shop, a repair shop, or a naval

Uneven tightening could cause overheating and

shipyard to have this done.

possible scoring of the shaft or the shaft sleeve.

To prevent water leakage between the shaft

On some centrifugal pumps, a lantern ring is

and the sleeve, some sleeves are packed, others

inserted between the rings of the packing. When

have an O-ring between the shaft and the

repacking stuffing boxes on such pumps, be sure

abutting shoulder. For detailed information,

to replace the packing beyond the lantern ring.

consult the appropriate manufacturer's technical

The packing should not block off the liquid seal

manual or applicable blueprint.

line connection to the lantern ring after the gland

has been tightened.

Renewing Wearing Rings.--The clearance

Figure 7-6 shows how the packing is arranged.

between the impeller and the casing wearing ring

Notice how the lantern ring lines up with the

(fig. 7-7) must be maintained as directed by the

liquid seal connection when the gland is tightened.

manufacturer. When clearances exceed the

specified amount, the casing wearing ring

Renewing Shaft Sleeves.--In some pumps the

must be replaced. On most ships, this job

shaft sleeve is pressed onto the shaft tightly by

can be done by the ship's force, but it requires

a hydraulic press. In this case, the old sleeve must

the complete disassembly of the pump. All

be machined off with a lathe before a new one

Figure 7-6.--Stuffing box on a centrifugal pump.

7-6