included in this classification, among which are

the gear pump, the screw pump, and the moving

vane pump. Unlike the centrifugal pump, which

we have discussed, the rotary pump is a positive-

displacement pump. This means that for each

revolution of the pump, a fixed volume of fluid

is moved regardless of the resistance against which

the pump is pushing. As you can see, any blockage

in the system could quickly cause damage to the

pump or a rupture of the system. You, as the

pump operator, must always be sure the system

is properly aligned so a complete flow path

exists for fluid flow. Also, because of their

positive displacement feature, rotary pumps

require a relief valve to protect the pump and

piping system. The relief valve lifts at a preset

pressure and returns the system liquid either to

the suction side of the pump or back to the supply

tank or sump.

Rotary pumps also differ from centrifugal

pumps in that they are essentially self-priming.

As we saw in our discussion of centrifugal pumps,

Insufficient suction pressure may cause vibration,

the pump is usually located below the liquid being

as well as noisy operation and fluctuating

pumped; gravity creates a static pressure head

discharge pressure.

which keeps the pump primed. A rotary pump can

operate within limits with the pump located above

the liquid being pumped.

Rotary Pumps

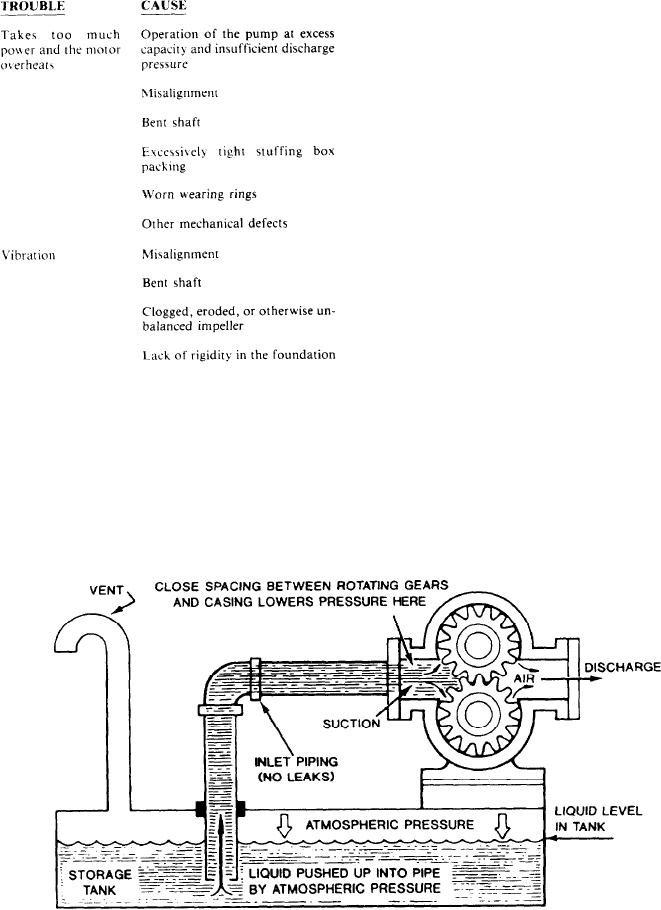

A good example of the principle that makes

Another type of pump you find aboard ship

rotary pumps self-priming is the simple drinking

is the rotary pump. A number of types are

Figure 7-8.--Gear pump located above the tank.

7-8