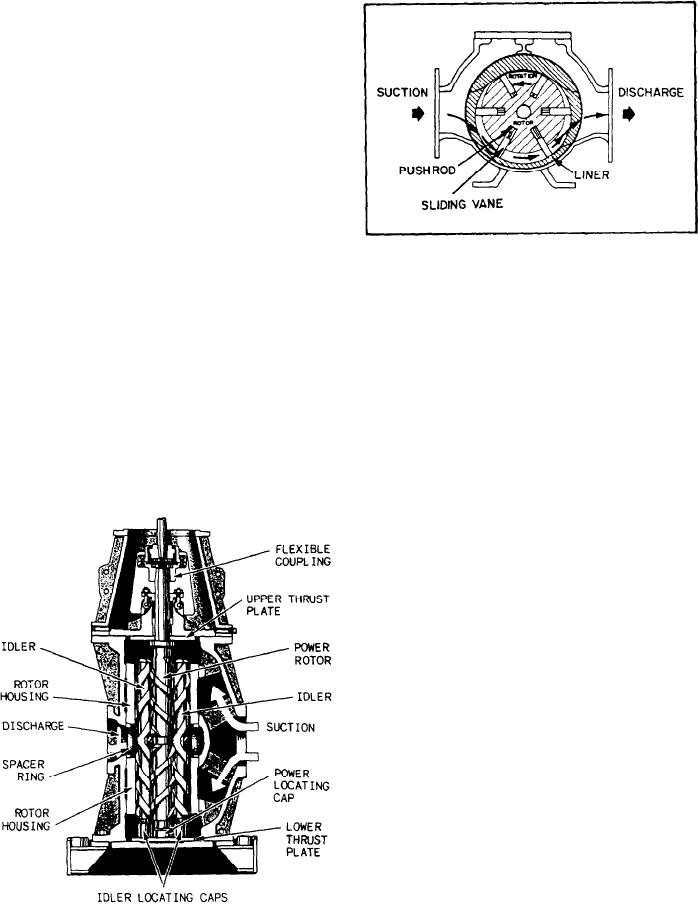

pump; and figure 7-11 shows a triple-screw, high-

pitch pump. Screw pumps are used aboard ship

to pump fuel and lube oil and to supply pressure

to the hydraulic system. In the double-screw

pump, one rotor is driven by the drive shaft and

the other by a set of timing gears. In the triple-

screw pump, a central rotor meshes with two idler

rotors.

In the screw pump, liquid is trapped and

forced through the pump by the action of rotating

screws. As the rotor turns, the liquid flows in be-

tween the threads at the outer end of each pair

of screws. The threads carry the liquid along

within the housing to the center of the pump,

where it is discharged.

Most screw pumps are now equipped with

Figure 7-12.--Sliding vane pump.

mechanical seals. If the mechanical seal fails, the

stuffing box has the capability of accepting two

The rotor carries vanes (which move in and

rings of conventional packing for emergency use.

out as the rotor rotates) to maintain sealed spaces

between the rotor and the cylinder wall. The vanes

SLIDING VANE PUMPS.--The sliding-vane

trap liquid on the suction side and carry it to the

pump (fig. 7-12) has a cylindrically bored

discharge side, where contraction of the space

housing with a suction inlet on one side and a

expels liquid through the discharge line. The vanes

discharge outlet on the other side. A rotor (smaller

slide on slots in the rotor. Vane pumps are used

in diameter than the cylinder) is driven about an

for lube oil service and transfer, tank stripping,

axis that is so placed above the center line of the

bilge, aircraft fueling and defueling, and, in

cylinder as to provide minimum clearance between

general, for handling lighter viscous liquids.

the rotor and cylinder at the top and maximum

clearance at the bottom.

Jet Pumps

The pumps discussed so far in this chapter

have had a variety of moving parts. One type of

pump you find in the engine room is the jet pump,

usually called an eductor. Figure 7-13 shows an

eductor, which has no moving parts. These pumps

are used for pumping large quantities of water

overboard in such applications as pumping bilges

and dewatering compartments. Eductors are also

being used on distilling plants as air or brine

eductors.

Eductors use a high-velocity jet of seawater

to lower the pressure in the chamber around the

converging nozzle. Seawater is supplied to the

converging nozzle at a relatively low velocity and

exits the nozzle at a high velocity. As the seawater

leaves the nozzle and passes through the chamber,

air becomes entrained in the jet stream and is

pumped out of the chamber. Pressure in the

chamber decreases, allowing atmospheric pressure

to push the surrounding water into the chamber

and mix with the jet stream. The diverging

nozzle allows the velocity of the fluid to decrease

and the pressure to increase; the discharge

pressure is then established.

Figure 7-11.--Triple-screw, high-pitch pump.

7-10