Classification of rotary pumps is generally

straw. As you suck on the straw, you lower the

air pressure inside the straw. Atmospheric

based on the types of rotating element. In the

following paragraphs, the main features of some

pressure on the surface of the liquid surrounding

common types of rotary pumps are described.

the straw is therefore greater and forces

the liquid up the straw. The same conditions

basically exist for the gear and screw pump

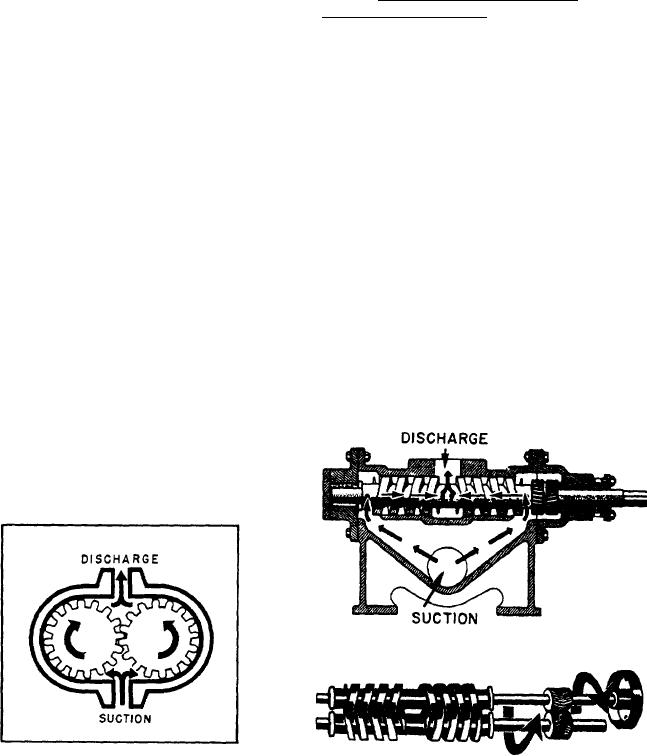

GEAR PUMPS.--The simple gear pump

to prime itself. Figure 7-8 shows a gear

( f i g . 7-9) has two spur gears that mesh

p u m p located above the tank. The tank

together and revolve in opposite directions. One

must be vented to allow air into the tank

is the driving gear, and the other is the

to provide atmospheric pressure on the sur-

driven gear. Clearances between the gear teeth

face of the liquid. To lower the pressure

(outside diameter of gear) and the casing and

on the suction side of the pump, the clear-

between the end face and the casing are only a

ances between the pump parts must be close

few thousandths of an inch. As the gears turn,

enough to pump air. When the pump starts,

the gears unmesh and liquid flows into the pockets

the air is pumped through the discharge

that are vacated by the meshing gear teeth. This

side of the pump and creates the low-pres-

creates the suction that draws the liquid into the

sure area on the suction side which allows

pump. The liquid is then carried along in the

the atmospheric pressure to force the liquid

pockets formed by the gear teeth and the casing.

up the pipe to the pump. To operate properly,

On the discharge side, the liquid is displaced by

the piping leading to the pump must have

the meshing of the gears and forced out through

no leaks or it will draw in air and can

the discharge side of the pump.

lose its prime.

One example of the use of a gear pump is in

Rotary pumps are useful for pumping oil and

the LM2500 engine fuel pump. However, gear

other heavy viscous liquids. In the engine room,

pumps are not used extensively on gas turbine

rotary pumps are used for handling lube oil and

ships.

fuel oil and are suitable for handling liquids over

a wide range of viscosities.

Rotary pumps are designed with very

SCREW PUMPS.--Several different types

small clearances between rotating parts and

of screw pumps exist. The differences be-

stationary parts to minimize leakage (slippage)

tween the various types are the number of

from the discharge side back to the suction

intermeshing screws and the pitch of the screws.

side. Rotary pumps are designed to operate

Figure 7-10 shows a double-screw, low-pitch

at relatively slow speeds to maintain these

clearances; operation at higher speeds causes

erosion and excessive wear, which result in

increased clearances with a subsequent decrease

in pumping capacity.

Figure 7-9.--Simple gear pump.

Figure 7-10.--Double-screw, low-pitch pump.

7-9