is thrown out through the opening around the

edge of the impeller and against the side of the

casing by centrifugal force. Centrifugal force is

force that is exerted upon a body or substance by

rotation. Centrifugal force impels the body or

substance outward from the axis of rotation.

When liquid is thrown out to the edge of

the casing, a region of low pressure (below

atmospheric) is created around the center of the

impeller; more liquid moves into the eye to replace

the liquid that was thrown out. Liquid moves

into the center of the impeller with a high velocity

(speed). Therefore, liquid in the center of the

impeller has a low pressure, but it is moving at

a high velocity.

Liquid moving between the blades of the

impeller spreads out, which causes the liquid to

slow down. (Its velocity decreases.) At the same

time, as the liquid moves closer to the edge of the

casing, the pressure of the liquid increases. This

change (from low pressure and high velocity at

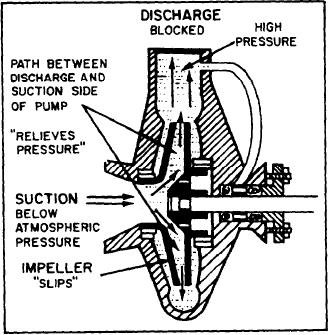

Figure 7-4.--Nonpositive-displacement pump.

the center to high pressure and low velocity at the

edge) is caused by the shape of the opening

pressure cannot occur because the passages in the

between the impeller blades. This space has the

impeller (between the discharge and suction side

shape of a diffuser, a device that causes the

of the pump) act like a built-in relief valve. When

velocity-pressure relationship of any fluid that

the discharge pressure and pressure head are equal

moves through it to change.

(as in this case), the impeller is allowed to rotate

(slips) through the liquid in the casing.

A centrifugal pump is considered to be a

nonpositive-displacement pump because the

volume of liquid discharged from the pump

NOTE: Centrifugal pumps used for inter-

changes whenever the pressure head changes. The

mittent service may have to run for long periods

pressure head is the combined effect of liquid

of time against a blocked discharge. Friction

weight, fluid friction, and obstruction to flow. In

between the impeller and the liquid raises the

a centrifugal pump, the force of the discharge

temperature of the liquid in the casing and causes

pressure of the pump must be able to overcome

the pump to overheat. To prevent this, a small

the force of the pressure head; otherwise, the

line is connected between the discharge and the

pump could not deliver any liquid to a piping

suction piping of the pump.

system. The pressure head and the discharge

pressure of a centrifugal pump oppose each other.

When a centrifugal pump is started, the vent

When the pressure head increases, the discharge

line must be opened to release entrained air. The

pressure of the pump must also increase. Since

open passage through the impeller of a centrifugal

no energy can be lost, when the discharge pressure

pump also causes another problem. It is possible

of the pump increases, the velocity of flow must

for liquid to flow backwards (reverse flow)

decrease. On the other hand, when the pressure

through the pump. A reverse flow, from the

head decreases, the volume of liquid discharged

discharge back to the suction, can happen when

from the pump increases. As a general rule, a

the pressure head overcomes the discharge

centrifugal pump is usually located below the

pressure of the pump. A reverse flow can also

liquid being pumped. (NOTE: This discussion

occur when the pump is not running and another

assumes a constant impeller speed.)

pump is delivering liquid to the same piping

system. To prevent a reverse flow of liquid

Figure 7-4 shows that when the pump

through a centrifugal pump, a check valve is

discharge is blocked, nothing happens because the

usually installed in the discharge line.

impeller is hollow. A tremendous buildup in

7-4