NOTE: Instead of two separate valves, some

installations use a globe stop-check valve.

With a check valve in the discharge line,

whenever the pressure above the disk rises above

the pressure below it, the check valve shuts. This

prevents liquid from flowing backwards through

the pump.

MAINTENANCE. --You must observe the

operation and safety precautions pertaining to

pumps by following the EOP subsystem of the

EOSS--if your ship has EOSS. If not, use Naval

Ships' Technical Manual and/or the instructions

posted on or near each individual pump. You

must follow the manufacturer's technical manual

o r MRCs for PMS-related work for all

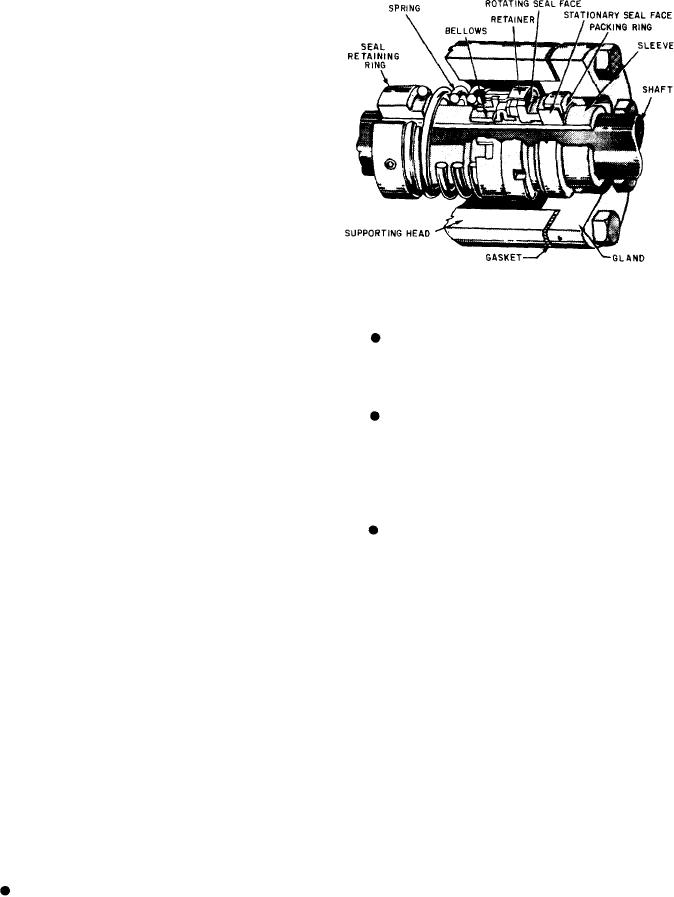

Figure 7-5.--Type-1 mechanical seal.

maintenance work. The MRCs list in detail what

you have to do for each individual maintenance

requirement.

Replace mechanical seals when the seal is

removed for any reason or when the

Mechanical Seals .--Mechanical seals are

leakage rate cannot be tolerated.

rapidly replacing conventional packing as the

means of controlling leakage on centrifugal

Position mechanical shaft seals on the

pumps. Pumps fitted with mechanical seals

shaft by stub or step sleeves. Shaft sleeves

eliminate the problem of excessive stuffing box

are chamfered (beveled) on outboard ends

leakage, which can result in pump and motor

to provide ease of mechanical seal

bearing failures and motor winding failures.

mounting.

Where mechanical shaft seals are used, the

design ensures that positive liquid pressure is

supplied to the seal faces under all conditions of

Do not position mechanical shaft seals by

operation and that there is adequate circulation

using setscrews.

of the liquid at the seal faces to minimize the

deposit of foreign matter on the seal parts.

Fire pumps and all seawater pumps installed

One type of a mechanical seal is shown in

in surface ships are being provided with

figure 7-5. Spring pressure keeps the rotating seal

mechanical shaft seals with cyclone separators.

face snug against the stationary seal face. The

The glands are designed to incorporate two or

rotating seal and all of the assembly below it are

more rings of packing if the mechanical shaft seal

affixed to the pump shaft. The stationary seal face

fails.

is held stationary by the seal gland and packing

ring. A static seal is formed between the two seal

A water flinger is fitted on the shaft

faces and the sleeve. System pressure within the

outboard of the stuffing box glands to prevent

pump assists the spring in keeping the rotating seal

leakage from the stuffing box following along

face tight against the stationary seal face. The type

the shaft and entering the bearing housings.

of material used for the seal face depends on the

They must fit tightly on the shaft. If the

service of the pump. When a seal wears out, it

flingers are fitted on the shaft sleeves instead

is simply replaced.

of on the shaft, ensure that no water leaks under

You should observe the following precautions

the sleeves.

when performing maintenance on mechanical

seals:

Stuffing Box Packing. --Although most cen-

Do not touch new seals on the sealing face

trifugal pumps on gas turbine ships have

because body acid and grease can cause the

mechanical seals, you should be familiar with

seal face to prematurely pit and fail.

stuffing box packing.

7-5