activated at the l-Hz rate. Depressing the FAULT

There are four alarm/status indicators

ALARM TEST activates the audible and visual

grouped under the heading JP-5 SERVICE. The

alarm indicators at l-Hz. The operator clears the

first indicator is a split-legend push-button

alarm in the same manner as for the hazard alarm.

indicator labeled HIGH and LOW. It illuminates

The second push button under the heading JP-5

HIGH when the PORT JP-5 service tank level

is labeled HAZARD ALARM TEST. Depressing

reaches 90 percent. It illuminates LOW if the tank

this push button allows the operator to perform

level drops to 10 percent. The second split-legend

a hazard alarm test of all alarm indicators on the

push-button indicator, labeled HIGH and LOW,

JP-5 control panel.

performs the same monitoring function for the

Depressing the FO hazard alarm test push

STBD service tank. The third split-legend control

button during actual fueling operations in the

push button displays the service pump ON or OFF

NORM mode will cause the receiving tank

status. Depressing this push button turns the

cutout valves and the main fill valve to close.

pump OFF if it is running, but the operator

Acknowledging the alarm by depressing the alarm

cannot start the pump from the FSCC. The fourth

indicator will stop the main fill valve from

indicator, labeled HIGH

PRESS, is an alarm

closing at whatever point it has reached. The

indicator for the JP-5 service filter separator

receiving tank valves will not stop closing but can

differential pressure. It illuminates amber if the

be opened by depressing the OPEN push button

differential pressure across the filter separator is

after acknowledging the fuel overflow alarm.

15 psid or greater.

Normally there is little maintenance necessary

Located on the right edge of the JP-5 control

for the FSCC. On most ships, the FSCC must be

panel is an annunciator labeled AUDIBLE

tested and calibrated before refueling. To perform

ALARM. It is a buzzer that provides the operator

these test and calibration procedures, the operator

with an audible indication that an alarm has been

must be familiar with the rear panel of the FSCC.

generated. Located to the right of the AUDIBLE

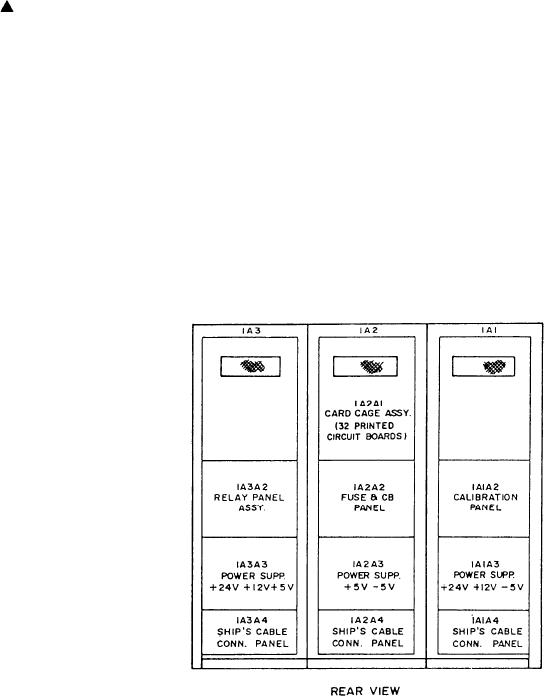

The rear panels will be discussed in a left-to-right,

ALARM is a status indicator labeled CONSOLE

top-to-bottom fashion. Refer to figure 9-12

HIGH TEMP. It illuminates amber to indicate

during this discussion.

the internal temperature of the FSCC has

exceeded a preset temperature.

Card Cage

Located on the right of the JP-5 control panel

Section 1A2A1 houses the card cage. It

of the FSCC are hazard, fault, and lamp test push

contains the 32 printed circuit boards (PCBs)

buttons. Depressing the individual push buttons

sends a test signal to the console electronics and

actuates the alarms. The first push button is under

the heading FUEL OIL. Depressing this push

button, labeled HAZARD ALARM TEST, causes

all the alarm indicators on the FO fill and transfer

control panel to flash at a 4-Hz rate and produces

an audible alarm. The operator must then depress

the individual alarm indicators to clear the alarms.

In fact, the operator must depress all the

indicators before the audible alarm will clear. The

HAZARD ALARM TEST indicates that the

alarms are operating correctly within their

prescribed setting. The second push button, under

the heading FUEL OIL AND JP-5, is labeled

LAMP TEST. Depressing this push button

illuminates all lights on the console, allowing the

operator to determine which light bulbs need

replacement. Releasing the push button completes

the test and extinguishes the lights. The last two

push buttons are under the heading JP-5. The first

push button, labeled FAULT ALARM TEST, is

used by the operator to test the system's alarm

circuitry. If a fault occurs, such as an open in

the wiring, audible and visual alarm indicators are

Figure 9-12.--Fuel system control console--rear view.

9-15