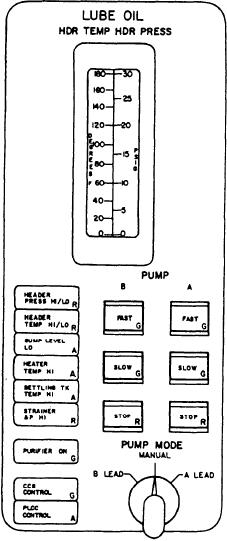

LUBE OIL Section

system. The other status indicator is amber

and labeled PLCC CONTROL. It illuminates

This section is used to monitor the MRG LO

when control of the LO system is at the

system. It has one dual-indicating meter, a

PLCC.

column of six alarm indicators (seven on

Under the label PUMP MODE is the three-

the CG console), three status indicators, six

position rotary switch. The positions are labeled

pump push-button control indicators, and a

B LEAD, MANUAL, and A LEAD. The PACC

three-position rotary switch for pump mode

operator uses this rotary switch to select either the

control.

manual mode of pump operation or the automatic

The dual-indicating meter is labeled HDR

mode. In the MANUAL mode the PACC

TEMP/HDR PRESS. It is used to monitor

operator can start (slow or fast) or stop the

the temperature and pressure of the LO at

electric LO pumps. The automatic mode is

the MRG header. The temperature side reads in

selected by placing the rotary switch in either the

degrees Fahrenheit and the pressure side reads

B LEAD or A LEAD position. The position

psig.

designated by the PACC operator determines

The alarm indicator labeled HEADER PRESS

which pump is the lead pump and which pump

HI/LO is the first of the six alarm indicators. It

is the standby pump.

illuminates red if the MRG LO pressure exceeds

27 psig or drops below 15 psig. Next is HEADER

TEMP HI/LO, which illuminates red if the MRG

LO temperature > 130F or is < 90F. The third

one is SUMP LEVEL LO, which illuminates

amber if the LO level in the MRG sump drops

below 1400 gallons. The alarm indicator labeled

HEATER TEMP HI illuminates amber if the LO

discharge temperature of the LO service system

heater exceeds 170F. The fifth alarm indicator

i s labeled SETTLING TK TEMP HI. It

illuminates amber if the temperature of the LO

in the settling tank exceeds 170F. The last one

is STRAINER DP HI. It illuminates red if the

differential pressure across the LO strainer

exceeds 10 psid.

Under the label PUMP are the six push-button

control indicators. There are two columns of three

push buttons for each pump (B or A). The PACC

operator uses these push buttons to control the

pump speed of either or both LO pumps. The

push buttons labeled FAST and SLOW are green

status switch/indicators that illuminate to show

the status or command to the respective pump,

depending on the operating mode the PACC

operator selects. The push buttons labeled STOP

are red status indicators that illuminate to

show the status or command to the respective

pump. On the CG console, the additional alarm

indicator labeled LO PURIFIER MALFUNCTION

illuminates red when a malfunction of the MRG

LO purifier occurs.

The status indicator labeled PURIFIER ON

illuminates green when the MRG LO purifier is

running. Under the PURIFIER ON indicator are

MIMIC PANEL

two status indicators. The first status indicator

is green and labeled CCS CONTROL. It

Figures 5-3 and 5-4 show a detailed view of

illuminates when CCS has control of the LO

the DD- and CG-class ships' PACC MIMIC

5-9