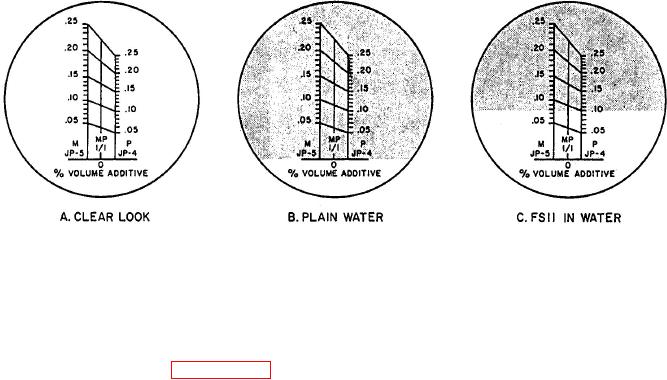

Figure 2-10.--Views through a refractometer.

Remove the black plastic rod from the

OILS

bottom of the refractometer. Using the rod

(or a screwdriver), adjust the setscrew

In the oil lab, your job of sampling and

until the shadow line meets the zero line of

testing oils (lubricants) will be extremely

the scale, as shown in figure 2-10. (Study

critical to the effective operation of your ship's

views A and B.)

engineering equipment and systems. Oils

reduce friction, dissipate heat, and prevent

corrosion. In addition, they conduct friction-

NOTE

generated heat away from bearings, act as a

seal to protect lubricated areas from

What you have done is added water to the

contamination, and act as a carrier for

fuel. By shaking the sample, you

have

materials such as rust preventatives, anti-

allowed the icing inhibitor to leach into the

friction

agents,

and

extreme-pressure

water. By adjusting the setscrew until you

additives.

read zero, you have made the refractometer

ready to compare the FSII in the fuel to the

Contamination of oils can seriously harm

scale inside the instrument.

equipment. Contamination occurs in oils

much in the same manner as it does in fuels.

10.

Open the plastic cover and wipe the

Whereas fuels are really used only once, oils

water from the window and cover.

are purified and used over and over again.

Carefully turn the drain cock so several

This is where a good sampling and testing

drops of water can trickle into a clean,

program comes into play.

dry aluminum dish. Open the hinged

plastic cover and place two or three

In the following sections, we will discuss

drops of water from the funnel on the

typical sampling and testing procedures for

window. Close the cover. Look through

oils. In most of our discussions, we will use

the eyepiece and read the point where

2190 TEP as a typical oil because you will

the shadow line is on the scale. This

come into contact with this oil more than any

reading should give you the percentage

of the others. Later in this section, we also

of FSII by volume. (Study view C.)

will tell you about the other types of oils and

the sampling and testing procedures you will

NOTE

be required to perform on them. Because you

will perform sampling more frequently than

Remember to put only water on the

testing, let's talk about oil sampling first.

refractometer, no fuel. Use clean water or

water with additives only. If fuel is in the

SAMPLING

sample you put on the refractometer, you may

get a false reading.

Oil sampling will always be your simplest,

most frequently used, and first-line procedure

11.

Upon completion of the test, empty the

of defense against equipment failure. While

funnel and properly dispose of the fuel.

assigned to the oil lab, you will need to know

Clean the equipment with soap and

the conditions for which you

water, then thoroughly rinse it with

water.