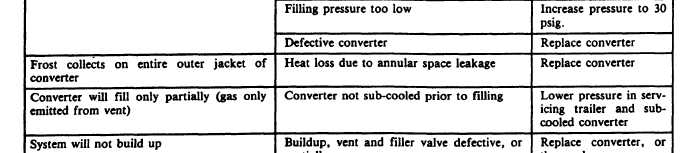

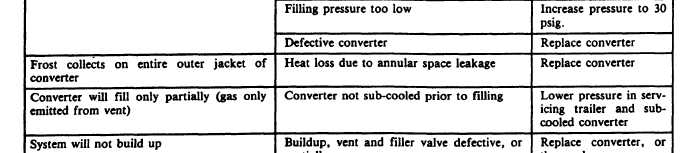

Table 12-17.—Troubleshooting (Acceptance/Turnaround/Daily/Preflight/Postflight and Transfer Inspections)

VISUAL INSPECTION

7. Security of supply,

quick-disconnects.

vent and electrical

Visually inspect the converter assembly and - 8. Excessive frosting of converter assembly.

surrounding area for the following:

9. Ensure date on converter bench test decal

1. Freedom from dirt and hydrocarbons.

2. Correct installation and positioning of all

components, safety wire, and Glyptal dots.

3.

4.

valves

5.

is current (within last 231 days).

Legibility of all markings.

Cracks, dents or other damage to

and electrical connections.

Corrosion on converter assembly and

functional test should also be performed by the

FUNCTIONAL TEST

tubing,

In addition to the scheduled test, the

surrounding areas.

AME whenever a component of the aircraft

6. Obstructions in aircraft overboard vent

oxygen system is removed/replaced. As a PR you

line.

may be called upon to perform this test. To

12-25