functionally test the converter assembly and air-

craft oxygen system, proceed as follows:

1. Ensure all circuit breakers associated with

the LOX quantity indicating system are set.

External electrical power must be applied to the

aircraft to perform steps 2 and 3 below.

2. Depress oxygen test switch. Check the

quantity gauge and low warning light for proper

operation. Refer to the applicable aircraft Hand-

book of Maintenance Instructions (HMI) to

determine at what quantity (indicated on quantity

gauge) that the low warning light should

illuminate.

3. Release test switch. Ensure gauge pointer

returns to position registered on gauge before

depressing. When test is completed, disconnect

electrical power for aircraft.

4. Ensure oxygen shutoff valve is in the OFF

position.

5. Attach an oxygen mask, regulator and

regulator-to-seat kit hose assembly to oxygen

supply connection in aircraft.

6. Turn oxygen shutoff valve to the ON posi-

tion. There should be a flow of oxygen through

the mask.

7. Place the mask against your face and

breathe. There should be a slight resistance during

exhalation. This resistance is due to the positive

pressure feature of the regulator.

8. Upon completing the functional test, turn

the oxygen shutoff valve to OFF. Disconnect the

regulator-to-seat kit hose from the aircraft supply

connection.

If discrepancies are found or suspected, notify

maintenance control.

Components of the aircraft oxygen system that

do not pass inspection and cannot be repaired in

the aircraft are removed and replaced by ready

for issue (RFI) components.

CALENDAR INSPECTION

All liquid oxygen converters are given the

calendar inspection before they are placed in

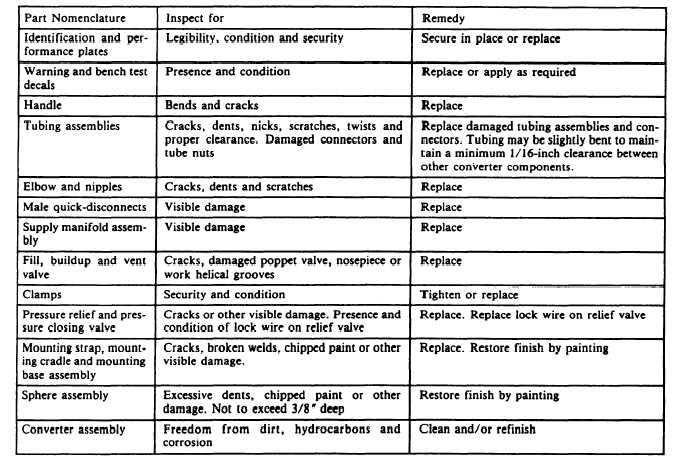

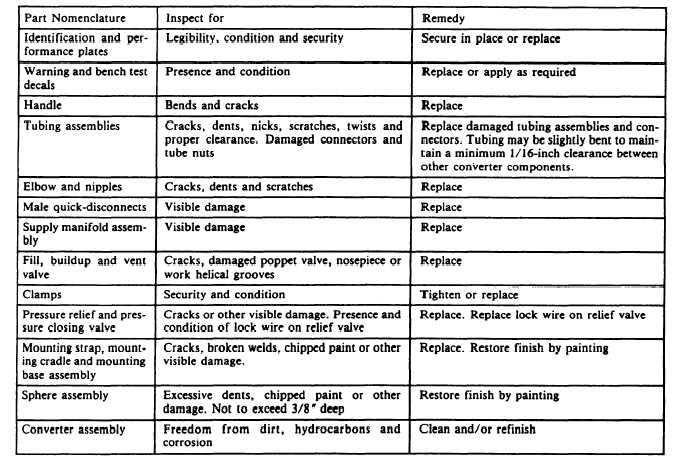

Table 12-18.—Visual Inspection of Type GCU-24/A Liquid Oxygen Converter (P/N 10C-0016-10)

12-26