pivoting at its lower end and moving the selector valve

The flap system discussed in this section is a

representative system. The number of flaps will vary

lever to the left. This action directs pressure from the

according to the size of the aircraft. The components

hydraulic system to the flap actuating cylinder (1). The

m a y h ave d i ff e r e n t n a m e s , d e p e n d i n g o n t h e

cylinder piston rod extends and lowers the flaps by

manufacturer, but the operational theory remains the

rotating the flap drive bell crank (3) in a clockwise

same. This system consists of a series of six flaps, three

direction. As the bell crank moves, the lower end of the

on the trailing edge of each wing. They raise and lower

floating arm moves to the right by the spring-loaded

in the conventional manner by a hydraulically actuated

pushrod (7). This action pivots the arm at its upper

linkage of bell cranks, pushrods, and idlers. The flap

connection to the sector pushrod and returns the

control lever in the cockpit controls the system

selector valve to neutral, stopping the action of the

mechanically. The lever connects by conventional and

system.

teleflex cables to the hydraulic actuating mechanism.

An emergency system is provided for lowering the

Moving the flap handle upward reverses the

flaps by operating a hand pump if the primary system

foregoing procedure by pushing the selector valve

malfunctions. The flap system has a position indicator

lever to the right, directing hydraulic pressure to the

and several safety devices to prevent lowering of the

retract side of the cylinder piston and raising the flaps.

flaps while the wings are folded, or folding of the

The follow-up rod then moves the lower end of the

wings while the flaps are lowered.

floating arm to the left and returns the selector valve to

neutral. The valve will not return completely to neutral,

The movement of the flap selector lever in the

maintaining pressure in the flap cylinder and ensuring

cockpit sets the flaps in motion. Movement of the

selector lever operates a cable quadrant to which a set

positive locking of the flaps in the up position.

of conventional control cables attach. These cables

The spring mechanism in the follow-up rod

connect to another sector just forward of the main wing

normally does not function. The spring mechanism is

beam. A teleflex cable, also attached to this aft sector,

provided only as a safety feature, permitting actuation

and a spring-loaded pushrod on the main flap actuating

of the flap drive crank by emergency hydraulic power if

bell crank connect to the two ends of a short floating

the selector valve becomes jammed.

arm installed on the hydraulic selector valve lever.

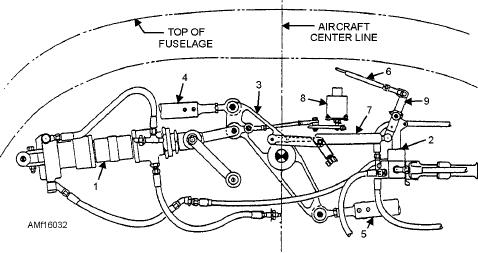

Figure 16-32 is a drawing of the cylinder, linkage, and

The flap hydraulic system consists primarily of the

selector valve installation. Reference to the index

selector valve and the actuating cylinder. See figure

numbers on this drawing is made in the following

16-33. The selector valve is a four-way, poppet-type

description of the operation of the flap control system.

valve. The poppets operate in pairs to direct pressure to

one side of the cylinder while opening the other side to

When the flap handle in the cockpit moves down,

reservoir return.

the upper end of the floating arm (9) pulls to the left,

1. Wing flap cylinder

4. Left flap contro pushrod

7. Follow-up pushrod

2. Wing flaps selector valve

5. Right flap control pushrod

8. Flap position transmitter

3. Flap actuating bell crank

6. Flap control push-pull cable assembly

9. Selector valve floating arm assembly

Figure 16-32.--Flap cylinder, linkage, and selector valve installation.

16-36