Swaging Equipment

Cable-Cutting Equipment

After the cable is cut, the next step in making up an

Cutting cables may be accomplished by any

aircraft cable is attachment of the terminals. Most

convenient method except an oxyacetylene cutting

terminal fittings are SWAGED onto the ends of control

torch. The method of cutting usually depends upon the

system cables. Swaging is essentially a squeezing

tools and machines available. If a cable tends to

process in which the cable is inserted into the barrel of

unravel, the ends may be sweat soldered or wrapped

the terminal. Then pressure is applied by dies in a

with a strip of tape prior to cutting.

swaging machine to compress the barrel of the

Small diameter cable may be cut satisfactorily

terminal tightly around the cable. The metal of the

with a pair of heavy-duty diagonal cutters, side cutters,

inside walls of the barrel is molded and cold flowed by

or a pair of wire nippers. Best results are obtained if the

force into the crevices of the cable. Figure 16-29 shows

cutting jaws are held perpendicular to the cable during

two types of hand-swaging tools. The one in the upper

the cutting operation. Cables up to 3/32 of an inch in

part of the illustration is mechanically operated, while

diameter may be cut in one operation by this method.

the lower one is pneumatically operated.

Larger cables may require two or more cuts. When you

When you prepare to swage a terminal, cut the

cut large diameter cables, use the end of the cutting

cable to the required length. Be sure to allow for the

blade, and cut only a few strands at a time.

elongation (increase in length due to stretching) of the

The most satisfactory method of cutting cables is

fitting that will occur during the swaging process. The

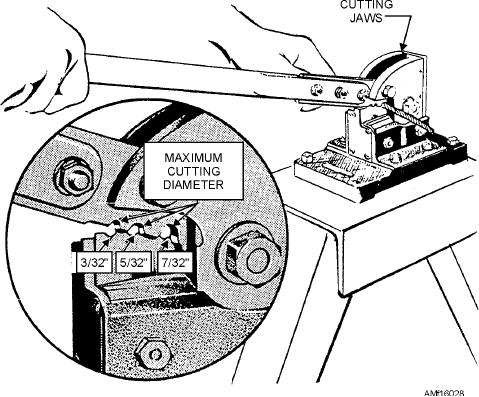

with a cable-cutting machine that has special jaws to

amount of elongation will vary with the type and size

accommodate various sizes of cable. See figure 16-28.

of fitting used. Therefore, the elongation must be taken

To use this machine, position the cable in the proper

into account whenever you make up any cable. The

diameter groove and hold the cable firmly within 2

Structural Hardware Manual, NAVAIR 01-1A-8,

inches of the cutting blades. Hold the cable at right

provides elongation data for all types and sizes of

angles to the cutting blades and pull the operating

fittings.

handle down sharply.

Make sure that the cable end is cut square and clean

A cold chisel and a soft metal block may also be

and that all strands remain in a compact group, as

used for cutting cables. This method should be used

shown in figure 16-30. Place a drop or two of light

only as a last resort because of the way the cable ends

lubricating oil on the cable end. Then, insert the end

into the terminal to a depth of about 1 inch. Bend the

will be frayed.

Figure 16-28.--Cable-cutting machine.

16-32