and group and work center supervisors to carry out

their duties more effectively and efficiently.

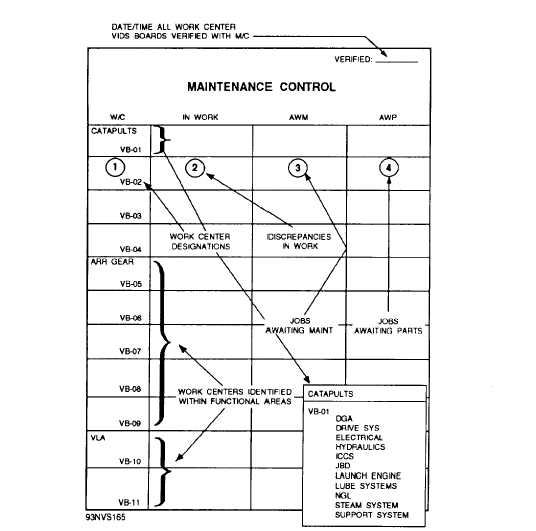

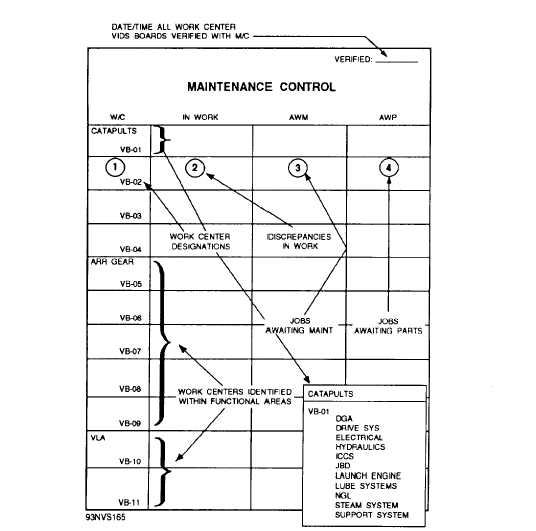

The maintenance control VIDS board (fig. 6-2)

displays maintenance information from all work

centers in the division. It and the work center

VIDS boards (fig. 6-3) are divided into sections

representing each work center. Each work center

section is identified by a standard work center

designation and is divided by line items to list

systems and equipment that are maintained by that

work center. The board is also divided into vertical

columns, for displaying information concerning

individual discrepancies or maintenance actions

effecting a specific system or piece of equipment.

Four columns are mandatory on the maintenance

control and all work center boards.

They are

(1) the column displaying the work center and work

center systems/equipment, as already mentioned;

(2) the In-Work column, which is used to display

in-progress maintenance actions; (3) the AWM or

Awaiting

Maintenance

column, to

display

maintenance actions that have been deferred; and

(4), the AWP or Awaiting Parts column, to display

maintenance actions that cannot be completed

because of a lack of parts or material. (Jobs

displayed in the AWM or AWP columns may

require the submission of a casualty report

[CASREP], due to lack of maintenance capability or

parts/material availability.)

Maintenance Action Form (MAF) Cards

MAF cards, figure 6-4, are used on the VIDs

boards to track all outstanding work center

maintenance actions, both on the work center and

maintenance control VIDs boards.

Before any

maintenance action is started, the responsible work

center must notify maintenance control. At this

time, work center and maintenance control MAF

Figure 6-2.—Maintenance control VIDS board.

6-6